The year 2022 has been a year of great progress and many milestones for CFCL, with our participation in Paris Fashion Week, becoming a Certified B Corporation, and the opening of our first directly managed store. Nevertheless, as communicated in past reports, we remain committed to create various benefits and impacts for our multiple stakeholders. As we enter our fourth year of rapid growth, we would like to continue to keep you informed of our diverse activities through this CONSCIOUSNESS REPORT.

Entering 2023, given the opportunity to work on the global stage, we successfully opened our second directly managed store, and inbound customers have been increasing since the beginning of the year. However, the global stage is facing more difficult times, including the ongoing impact of the COVID-19 pandemic on the supply chain and soaring energy prices due to Russia’s invasion of Ukraine which began last year, as well as the extreme weather such as drought in Africa and water shortages in Europe.

Taking these circumstance into account, we will continue our activities while carefully each and every initiative that makes the most of Japanese domestic production, and its technologies and strengths. Among our many new attempts, we have selected the following three topics for this report.

1. LCA (Life Cycle Assessment)

Verification results of new products such as the popular MILAN RIB, POTTERY, and FLUTED series cardigans

2. Procurement of Materials

Usage rate of materials that are certified as being responsible for the global environment and basic human rights, in all products

3. Creating Benefits for the Community

3-1. Interaction with B Corp Community

3-2. Participation in B Corp Month Japan

3-3. Joining the Japan Sustainable Fashion Alliance

In our previous reports, items with various parts (such as button, zipper, linings, etc.) that are often seen as accessories to garments were excluded from our LCA. This is because the most minimalistic garments, are the main products that act as the most straightforward expression of the CFCL brand concept.

On the other hand, CFCL is also working on manufacturing garments with the minimum number of necessary parts in order to allow a wider variety of creations and to increase durability for a longer life span of the garments.

Therefore, in VOL.5, we expanded the scope of our assessment to include “items with parts” for the first time.

Now that we have a clear understanding of how the manufacturing structure (or business model) of garments with these parts creates the environmental impact of greenhouse gas (GHG) emissions and what we need to address, we can move forward with further challenges.

Most of the clothing in the world are made with many of these parts, but there are very few LCA examples to determine the environmental impact, so we hope that this report will be of act as a benchmark for the apparel industry.

Products Covered in VOL.5

MILAN RIB JACKET 2: 14.08kg-CO2e / 1pc

MILAN RIB PANTS 2: 15.81kg-CO2e / 1pc

The MLIAN RIB jacket and pants set-up series has become the mainstay of the men’s lineup due to a significant increase in the number of customers trying on these items since the opening of CFCL’s direct managed store in October 2022. Compared to items for which LCA has been conducted, these products have the most parts in the CFCL product line, including buttons, zippers, lining, various adjustments and piping (strings, tapes, etc.) for the waist.

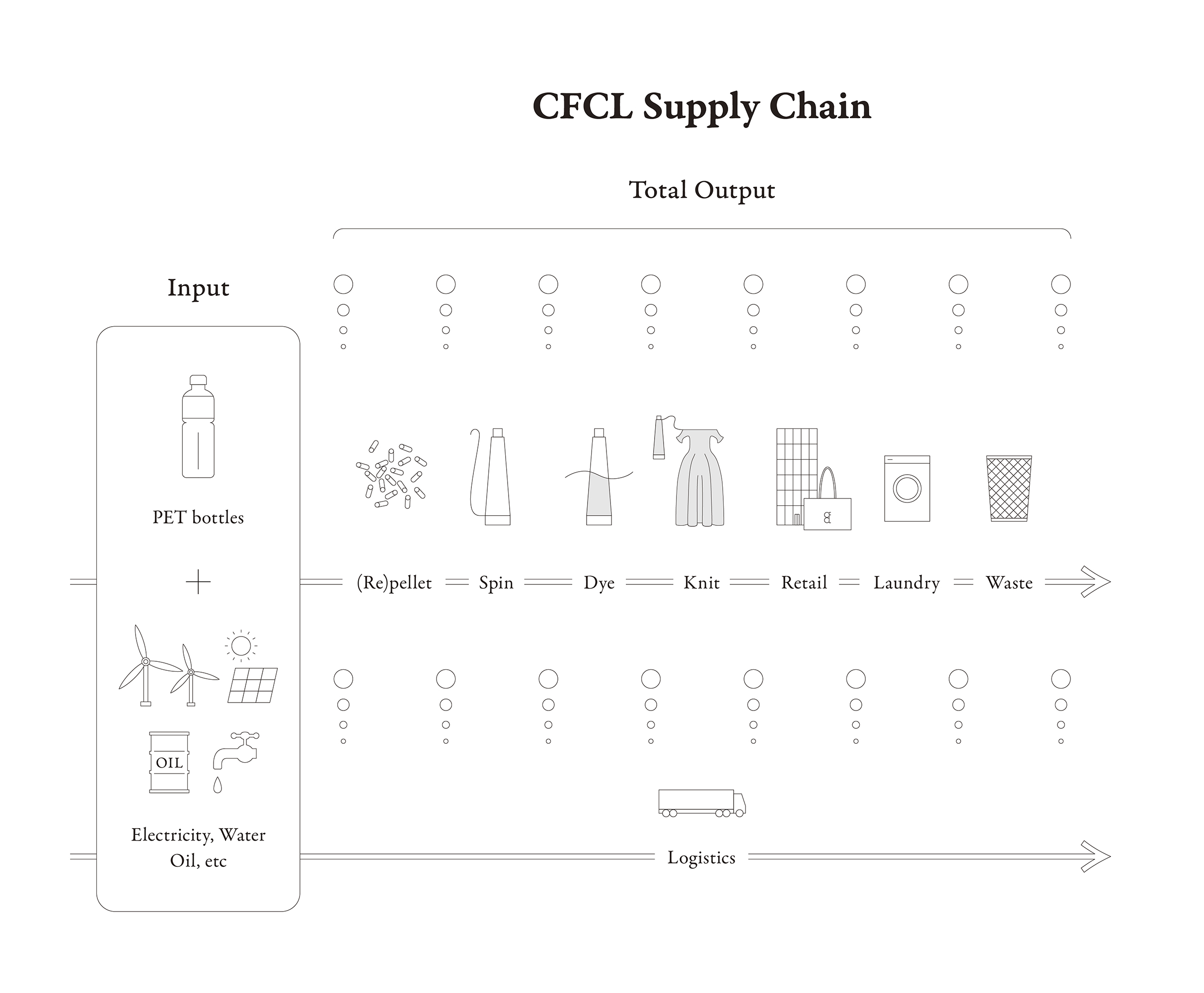

This time, we assessed the GHG emissions indicated above, with the cooperation of direct/indirect suppliers and business partners in the supply chain from the procurement of raw materials, processing of parts and materials, knit manufacturers, logistics and sales, customers, and post-consumer final disposal after wearing.

・Composed of 6 major parts

(Yarn for the main body of the garment such as the front and back, lining, buttons, zippers, and strings and tapes around the waist)

・5 major raw materials for each of the 6 parts

(Post-consumer waste recycled polyester, virgin polyester from crude oil mining, nylon, polyurethane, and acrylic)

・11 companies with whom we communicated directly in conducting LCA

・Approximately 200 companies/organizations that cooperated directly or indirectly

Compared to the Japan average emission of 25.5 kg-CO2e per garment (*1), the MILAN RIB jacket and pants are about 40% lower in GHG emissions.

Challenges: Although we have worked on manufacturing products with low carbon emissions by producing them in Japan, using recycled materials, and procuring some of those recycled raw materials collected in Japan, we found the following challenges from our analysis.

(1) The use of recycled materials at a low rate of 18~19% is the main reason for approximately 40% of GHG emissions, so we must first increase the use of recycled materials such as post-consumer PET bottles to 100%.

(2) Introduce renewable energy centering on solar and wind power at manufacturing plants.

Countermeasures: Regarding (1), we have already started sharing these topics and trial production with material manufacturers and knitting manufacturers since last year. Mass production tests have been completed, and we have already started production of items officially adopted from our next season, VOL.6.

*1. Japan Ministry of Environment “Fashion and the Environment” Survey Results

POTTERY CARDIGAN 1: 1.65kg-CO2e / 1pc

This cardigan is produced by our knitting manufacturing partner in Tokyo, which is in the same area as the CFCL office. After the manufacturer moved to a new facility (still in Tokyo) last autumn, due to their strong will despite the risk of cost burden, they immediately introduced 100% renewable energy, mainly solar and wind power, instead of conventional high GHG emission energy sources. Because of their strong policy and environmental decision making, this cardigan can be produced in extremely low GHG emissions. All yarns and accessories are made of 100% post-consumer PET bottle recycled materials.

FLUTED CARDIGAN 1: 6.73kg-CO2e / 1pc

FLUTED is another iconic series for CFCL after the POTTERY series. The items are manufactured by our knitting manufacturer in Niigata prefecture, one of the leading knit production centers in Japan. Not only this cardigan, but also many other items such as the above-mentioned MILAN RIB jackets and pants are produced with the manufacturer’s extremely high technology. Although FLUTED CARDIGAN takes 2.3 times longer to knit and weighs 3 times more than the POTTERY series, this manufacturer’s extremely low defect rate and and advanced technology backed by extensive experience enable production with a low environmental impact that being consistent with our minimum waste policy. Starting this year, together, we are working on the best way to introduce 100% renewable energy, with mainly solar and wind power.

Reference:

・Calculated using IDEAv2.3 (LCI database IDEA version2.3, National Institute of Advanced Industrial Science and Technology Research Institute of Science for Safety and Sustainability, Sustainable Management Promotion Organization, LCA Research Group Safety Science Research Division,)

・Eionet Report – ETC/WMGE 2021/3 Greenhouse gas emissions and natural capital implications of plastics (including biobased plastics) (ETC_2.1.2.1._GHGEmissionsOfPlastics_FinalReport_v7.0_ED)

・The Association of Plastic Recyclers White Paper: Virgin vs. Recycled Plastic Life Cycle Assessment Energy Profile and Life Cycle Assessment Environmental Burdens. May 12, 2020

・Higg Product Tools Material Sustainability Index

・Discussion of LCA (Plastic Waste Management Institute)

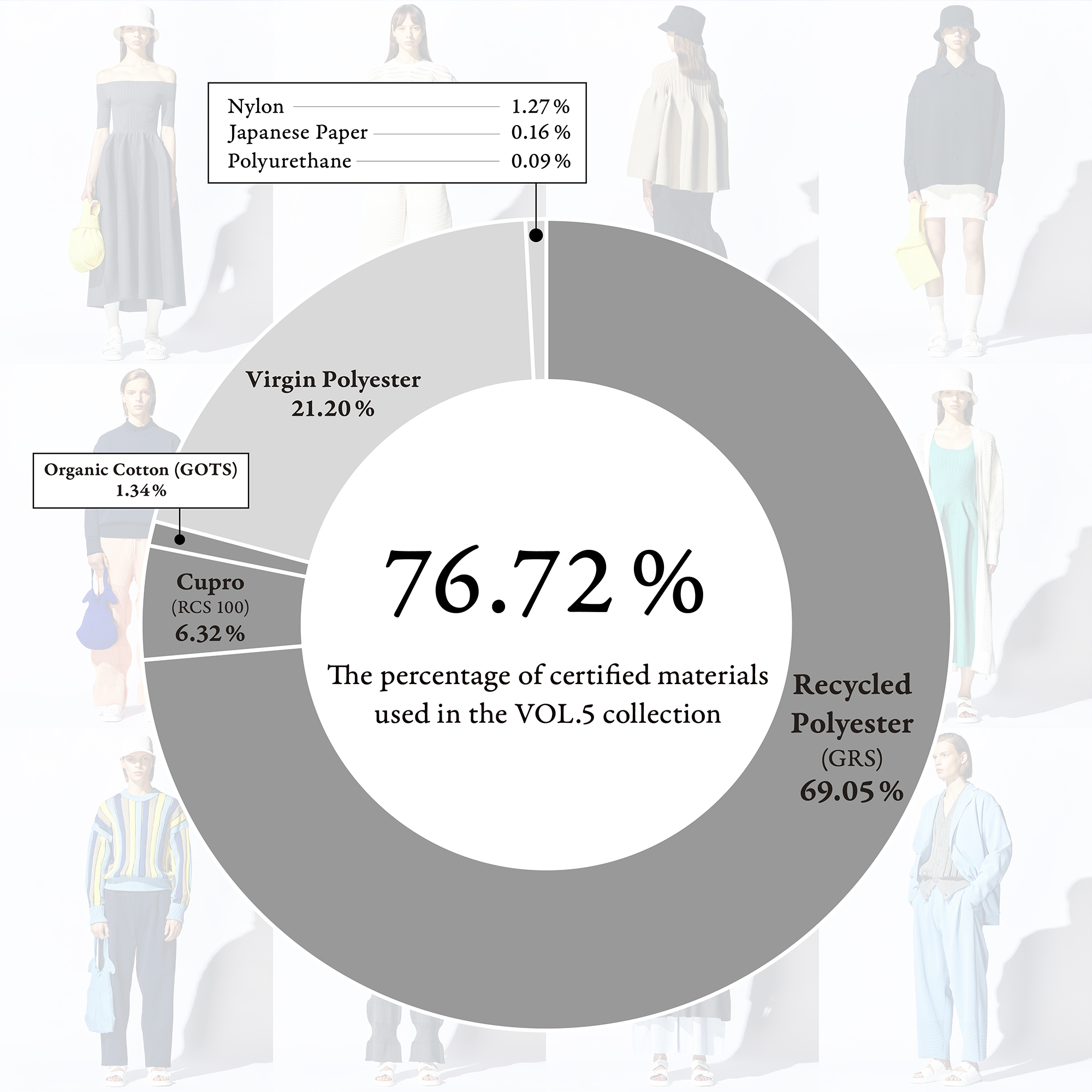

76.72%

Materials that are 100% recycled and that guarantee a healthy working environment for people at the production site, as well as materials that guarantee that they are organic. In VOL.5, the total usage rate of these materials certified by third-party organizations further expanded to 76.72%, the highest among the collections announced in the past. There is a 10.38% increase compared to VOL.3 (2022), the same spring summer season.

As a result of challenging new creations with participation in Paris Fashion Week, the number of styles soared more than three times when compared to our VOL.3 collection, the same spring summer season from the previous year. New items using see-through and stretchy yarns, as well as the sacoche and other bags, were added to the collection, expanding the range of designs and variations. Virgin materials (*2) such as nylon and polyurethane, which are not yet recycled materials so far, are sometimes used for waist bands and pocket linings. These are common items of clothing used widely in the entire apparel industry, but even in this situation, we will continue to actively use these certified materials and work with our manufacturing partners that produce with natural energy.

Expanding the number of products and the scale of sales turnover is something that most businesses do. On the other hand, that is what businesses have done in the past. In order to keep creating circular and low-carbon society, eliminating disparities and discrimination, and addressing other ever-growing problems, it is necessary to build a new form of business. At B Corp, we evaluate the level of “governance” as the ability to make such a long-term commitment. However, the reality of the market is that recycled materials, even polyester, which is the most widely distributed material in the market, is about 10~20% more expensive than virgin materials at around 10% share in the Japanese market, and renewable energy is still 10~20% more expensive than oil, coal, and other climate crisis-causing energies. This is a critical issue for business, especially for CFCL and our manufacturing partners, which do not have lavish finance. It would never be easy to continue to make such choices, but CFCL has only been in business for just 3 years. Continuing this essential challenge is a must for us, and for everybody.

When looking ahead to a society in which all materials and energy are recycled and regenerated, it is not an easy task. However, some positive changes are steadily taking place, such as an increase in the number of appropriate materials proposed by manufacturers and trading companies compared to the time of VOL.1 in year of 2020. We would like to once again express our respect for the developments that are underway at each company and their social and environmental investment decision making.

The VOL.6 products, that has already complete sample prototyping, will begin using new recycled polyester yarns. The design team will work closely together with each manufacturing partner to surpass the highest usage rate of VOL.5, 76.72%.

*2 A method of producing polyester yarn, a plastic, that is produced by mining crude oil from scratch. Mainstream research shows that GHG emissions are on average 50% higher than those of recycled materials.

1. Interaction with B Corp Community

Since being certified as a B Corp last July, communication has been activated with domestic and international B Corps, companies and academic institutions interested in B Corp, and corporations and individuals whose vectors are aligned with the B Corp movement. In addition, the B Corp community in Japan has an online meeting once every two months, where a wide range of issues, business potentials, case studies, and examples of initiatives by each company are discussed regardless of industry boundaries. The new initiatives and business models of each company as a real global standard are also shared several times with the Cabinet Secretariat as benchmarks for the “New Form of Capitalism” proposed by the Japanese government starting in 2021 in areas of all stakeholders such as the global environment, local communities, human and social diversity, and work styles.

2. B Corp Month JAPAN

Every March, B Corps around the world meet in a variety of ways, where events, networking, and business meetings are held in a variety of formats, providing a venue for new initiatives to emerge. In Japan, B Corp Month JAPAN was held for the first time on March 11th, 2023 at 100BANCH in Shibuya-ku, Tokyo, bringing together 22 certified B Corps, as well as supportive organizations and volunteers. Their products were exhibited and introduced, and a panel discussion with participation from Allbirds U.S. headquarters was also held.

CFCL moderated an open discussion that included many companies, media, and government officials, as well as certified B Corps such as FERMENSTATION Co.,Ltd., Patagonia Japan, Danone Japan, and so on.

In this year’s B Corp month, which had a universal theme of “Beyond,” we carried out discussion while focusing on how we can build a transparent supply chain as a business, to create benefits for a wider range of people and planet earth.

We will keep you informed on the short and long-term outcomes of these activities in our CONSCIOUSNESS REPORT.

3. Japan Sustainable Fashion Alliance (JSFA)

In January 2023, CFCL joined the Japan Sustainable Fashion Alliance (JSFA), an alliance of companies involved in fashion related businesses working together to promote sustainable fashion.

With the goal of 2050, each participating company will work together to achieve carbon neutrality and zero fashion loss, as well as to solve related problems.

*JSFA HP:https://jsfa.info/#about