CFCL was founded in 2020, with the fundamental aim of contributing to the benefit for all stakeholders—customers, employees, environment and local communities including business partners—through the clothes we make and activities we carryout. We pursue not only the quality and functionality of our garments, but also the way we do business, the way we work, as well as the way we use material and energy throughout our supply chain.

CFCL released our very first collection “VOL.1” in January 2021. Through one of our main items, the “POTTERY DRESS”, there are three topics that convey our specific activities and results.

1. LCA: In order to understand our environmental impact in the face of the global climate crisis, we conducted Life Cycle Assessment (LCA), which is the first of its kind within the Japanese fashion and apparel industry.

2. Usage rate of materials certified: As a result of our material selection activities, which are important in reducing our impact to our stakeholders, we calculated the usage rate of materials certified as responsible for the global environment and basic human rights.

3. Upcycle: We produced and sold limited edition items that were upcycled using the remaining yarn from seasonal items.

We invite you to continue reading onward to discover more about our endeavors toward sustainability.

Have you ever heard of the term “carbon neutral”?

Carbon neutrality is an effort to drastically reduce emissions of greenhouse gases such as carbon dioxide and methane (which are the cause of global warming), to virtually zero.

So far, it is deemed impossible, to entirely use renewable energy sources such as solar power, for all our work; this includes the materials used in our manufacturing process, the energy used to run our facilities, and the cars and airplanes we use for business trips. However, it is essential to use more recycled materials and plant trees. Therefore, CFCL uses a lot of recycled materials and promotes carbon dioxide absorption through activities such as tree planting, in order to numerically reduce the amount of greenhouse gases to a real zero by “offsetting” the greenhouse gases generated and (theoretically) absorbed.

The Japanese government has also committed to achieve carbon neutrality by the year 2050, although major countries and advanced companies around the world are already ahead of the curve.

Therefore, CFCL conducted a LCA (Life Cycle Assessment) for the launch of our first collection “VOL.1”, which is the first attempt made within the Japanese apparel industry.

LCA is a method of visualizing how much greenhouse gas is generated throughout its life cycle (from raw material procurement to disposal), calculated and quantified based on the International Standard ISO 14040. It is a necessary step toward the realization of a carbon-neutral and recycling-oriented society. (*1)

POTTERY DRESS (short sleeve) 4.99 kg-CO2e/1 pc

This is the amount of greenhouse gas (GHG) emissions per piece of POTTERY DRESS (weight approx. 540 g), from VOL.1. There are various types of greenhouse gases, but we use the unit “CO2e” to express all of them as numerical values converted to carbon dioxide. From the process of making the yarn for the dress, you can see that it emits the above amount of carbon dioxide before it is used by customers for many years and discarded. (* 2)

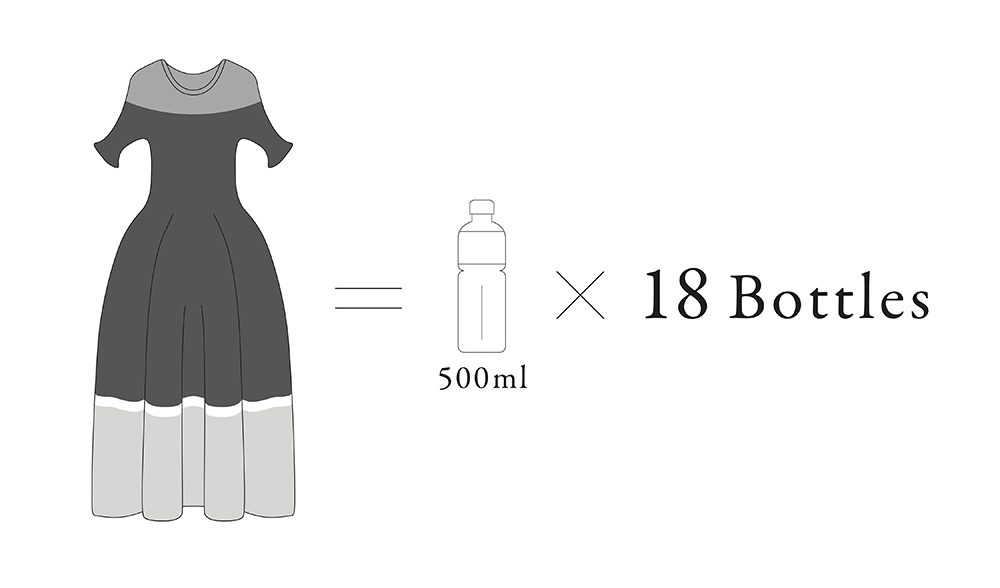

In fact, the POTTERY DRESS is made by reusing about 18 plastic bottles that would have otherwise been trashed. It is said that the use of recycled yarn from plastic bottles reduces greenhouse gas emissions by about 50% compared to the use of petroleum-derived polyester yarn. (*3) In addition, while most fashion clothing is now produced in China and Southeast Asia, the POTTERY DRESS is manufactured almost entirely in Japan, reducing greenhouse gas emissions in terms of transportation as well.

CFCL aims to reduce these emissions to virtually zero (=carbon neutral) by 2030, 20 years earlier than the Japanese government’s goal of 2050. With the cooperation of all supplier and partners involved in the life cycle, we will make various efforts to achieve this goal, including the selection of material.

*1: The amount is calculated using IDEA v2.3. (LCI Database IDEA Version 2.3, Japanese National Research and Development Agency, Advanced Industrial Science and Technology, The Research Institute of Science for Safety and Sustainability and LCA Research Group, Sustainable Management Promotion Organization)

*2: As reference, a research result shows that a single T-shirt (150 g) produced from conventional cotton emits 3.4 kg-CO2e of greenhouse gases. (“Analysis of inventory of CO2 and water intended for clothes” – Norihiro Itsubo Laboratory, Department of Environmental Studies, Tokyo City University)

*3: In-house research.

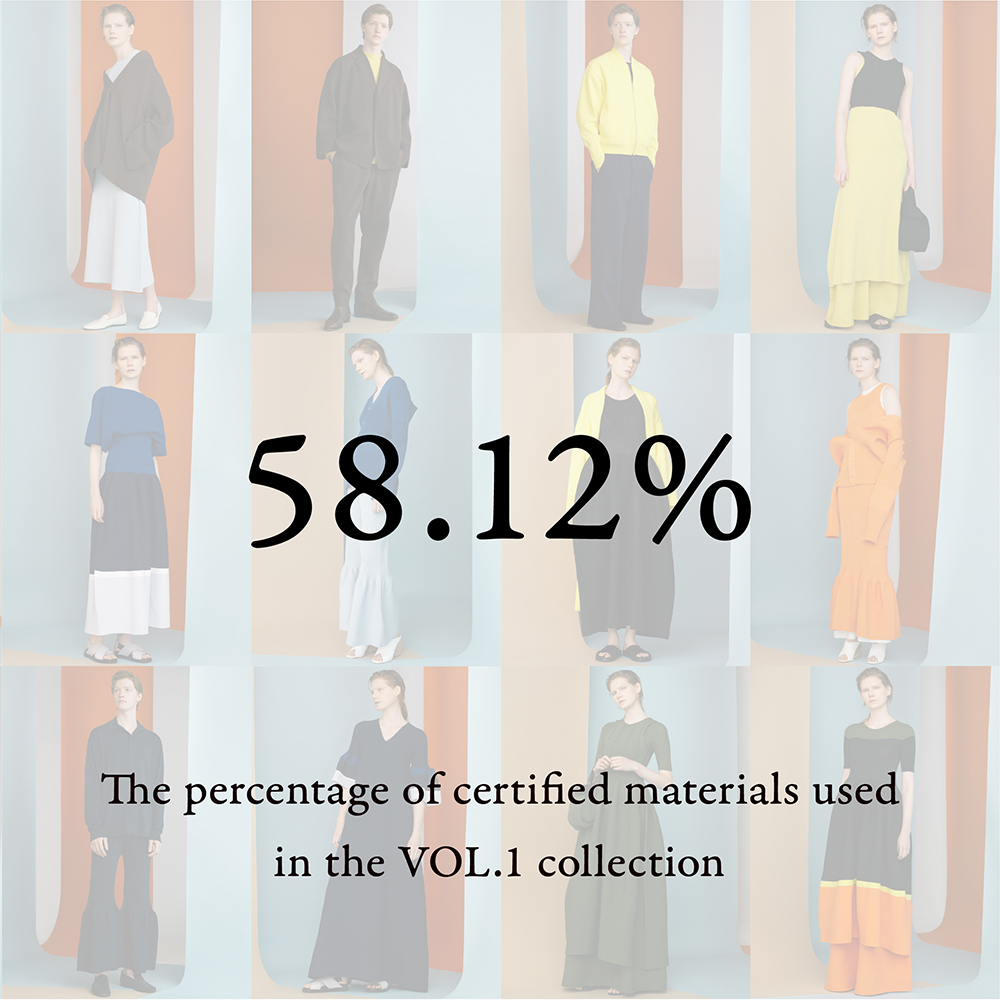

The above figures indicate the usage rates of yarn that reduce the burden on the global environment and guarantee soundness from the viewpoint of human rights protection, during mass production of the CFCL VOL.1 collection. This certification system we rely on is called the “Global Recycling Standard (GRS) (*1)”, which calculates (*2) how much materials that meet these international standards are used for all products, including custom-made products.

On the other hand, although “recycled materials,” “biodegradable materials,” “marine degradable materials,” and “materials that suppress the use of petroleum” have appeared in the market especially in recent years, there are many materials that acquire GRS and cannot be said to really reduce environmental impact. Materials that can be used by customers for a long time are still extremely limited, and the current situation is that there are few variations.

CFCL uses recycled fiber for all items in VOL.1. However, due to the above reasons, there are items in our product lineup that currently does not use 100% recycled fiber per piece of clothing.

CFCL aims to be a skin-like entity where people can feel the joy of wearing clothes and live comfortably, while realizing their own contemporary lifestyle. However, no matter how much environmentally friendly materials we use, if this purpose is not achieved, unfortunately our clothes will be discarded after being worn for a short period of time, and it will be different from the clothes we strive to create.

By focusing on recycled materials, we aim to produce clothes that reduce the environmental impact 100% by 2030, as we continue to disclose the numerical values of usage rates and develop better materials with raw materials and material manufacturers.

*1: The Global Recycled Standard (GRS) is a certification program developed by the Control Union Certification in 2008, which was later transferred to the Textile Exchange in 2011. GRS is an international product standard that sets third-party certification requirements for recycled content, processing and distribution process management, social and environmental practices, and chemical regulations. All the certified materials used in the VOL. 1 collection are GRS certified.

*2: This calculation does not include accessories such as buttons, zippers, strings, and waist elastics.

CFCL VOL.1 Collection – UPCYCLED POTTERY SERIES

The “POTTERY” series, introduced in CFCL VOL.1, has a symbolic rounded silhouette like a pot.

To create this series, we took the remaining yarn left over to make a bi-colored top and skirt in two colors, to up-cycle and prevent waste. Normally, the remaining yarns are disposed of, however, since incineration generates greenhouse gas emissions, the up-cycling business model avoids this problem. The unique items are knitted with multiple colors of mixed yarn, each created by pulling together 2 colors out of orange, khaki, and light gray. Through this technique, we transformed the series with a new look, while still maintaining the voluminous silhouette. Like the other “POTTERY” series items, with the use of 100% recycled polyester and computer-programmed knitting technology, these items are seamless, comfortable, and washable.