In the manufacturing of our garments, CFCL pursues not only functionality but solidarity with local communities, selection of optimal domestic materials, and transparency of the supply chain while considering the global environment in the production of garments. Continuing from the previous season, we have been conducting Life Cycle Assessment (LCA) to recognize the greenhouse gases (GHG) emission impact we generate. We also calculate the usage rate of materials certified as responsible for the global environment and basic human rights, as well as offer limited edition upcycled items using the remaining yarn from seasonal items. As a new initiative for this season, we conducted a questionnaire on the SDGs Performance Guideline to our manufacturing suppliers.

As mentioned in our VOL.1 Consciousness report, Japan’s target for achieving carbon neutrality is 2050, like other advanced countries. As an interim target for 2030, Japan needs to reduce GHG emissions by 46% compared to 2013.

In May of 2021, CFCL completed its formal application to obtain the “B Corp” certification. However, many companies around the world have already obtained this certification with an aim to achieve carbon neutrality before 2030.

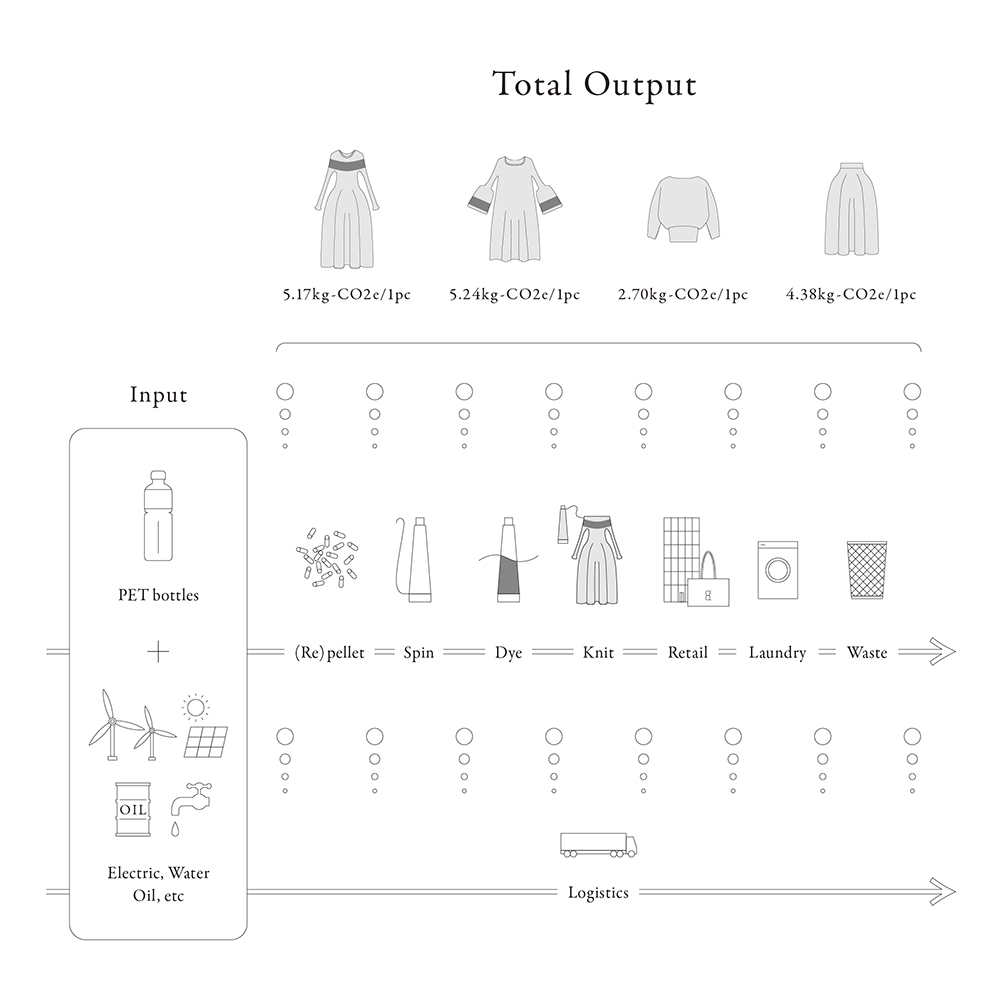

Based on the above, CFCL conducted LCA (Life Cycle Assessment) following the previous season. (* 1) For VOL.2, the scope of LCA is expanded to all 4 styles from the POTTERY series. In our journey to do better, we constantly search for the optimal decarbonization approach every day by accurately grasping the carbon emissions that our company produces. Ultimately, we aim to cover all POTTERY styles by 2025.

VOL. 2 Details of Implementation (Announced in July 2021): Please refer to the following for the GHG emission details for the 4 styles within our POTTERY series. Out of 36 styles, we calculated 4 styles, which is about 11% out of the entire season.

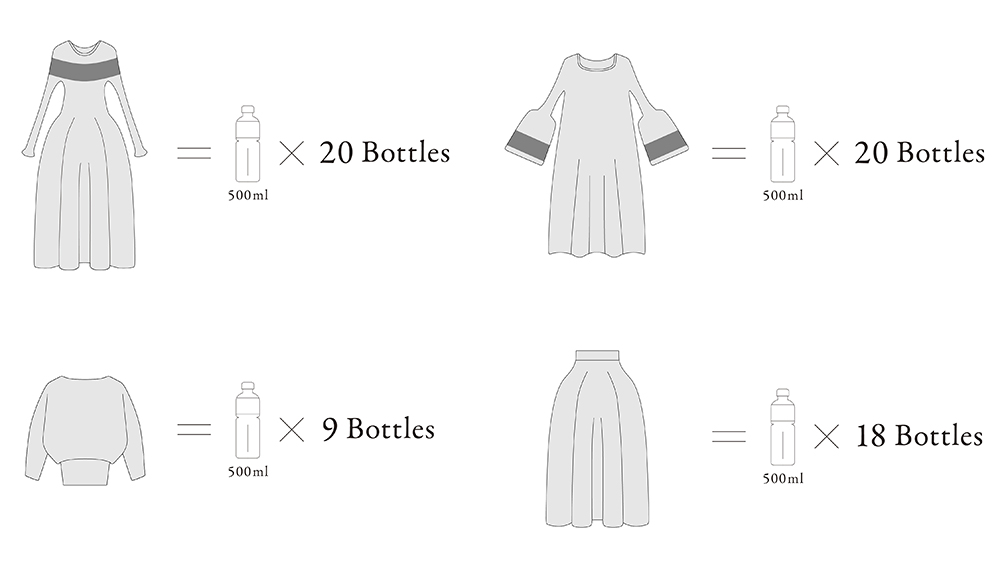

1. POTTERY DRESS(long sleeve)5.17 kg-CO2e/1 pc (Equivalent to 20 bottles of a 30 g/500 ml PET bottle)

2. POTTERY KAFTAN(long sleeve)5.24 kg-CO2e/1 pc (Equivalent to 20 bottles of a 30 g/500 ml PET bottle)

3. POTTERY TOP 2.70 kg-CO2e/1 pc(Equivalent to 9 bottles of a 30 g/500 ml PET bottle)

4. POTTERY SKIRT 4.38 kg-CO2e/1 pc(Equivalent to 18 bottles of a 30 g/500 ml PET bottle)

CFCL aims to reduce these emissions to virtually zero (=carbon neutral) by 2030, 20 years earlier than the Japanese government’s goal of 2050. To achieve this goal, we will make various efforts, including the selection of material, with the cooperation of all suppliers and partners involved in the life cycle.

While updating all these elements, we also aim to solve social issues represented within the SDGs.

※POTTERY DRESS made from recycled PET bottle yarn reduces GHG emissions by about 50% compared to when it is made from virgin polyester. (*2)

※One research shows that “a single T-shirt (150 g) produced with conventional cotton emits 3.4 kg-CO2e of greenhouse gas” (*3), and if the weight is the same as one POTTERY DRESS, it is equivalent to “more than 10 kg-CO2e” of GHG emissions when made with conventional cotton.

*1: The amount is calculated using IDEA v2.3. (LCI Database IDEA Version 2.3, Japanese National Research and Development Agency, Advanced industrial Science and Technology, The Research Institute of Science for Safety and Sustainability and LCA Research Group, Sustainable Management Promotion Organization)

*2: In-house research.

*3: “Analysis of inventory of CO2 and water intended for clothes” – Norihiro Itsubo Laboratory, Department of Environmental Studies, Tokyo City University

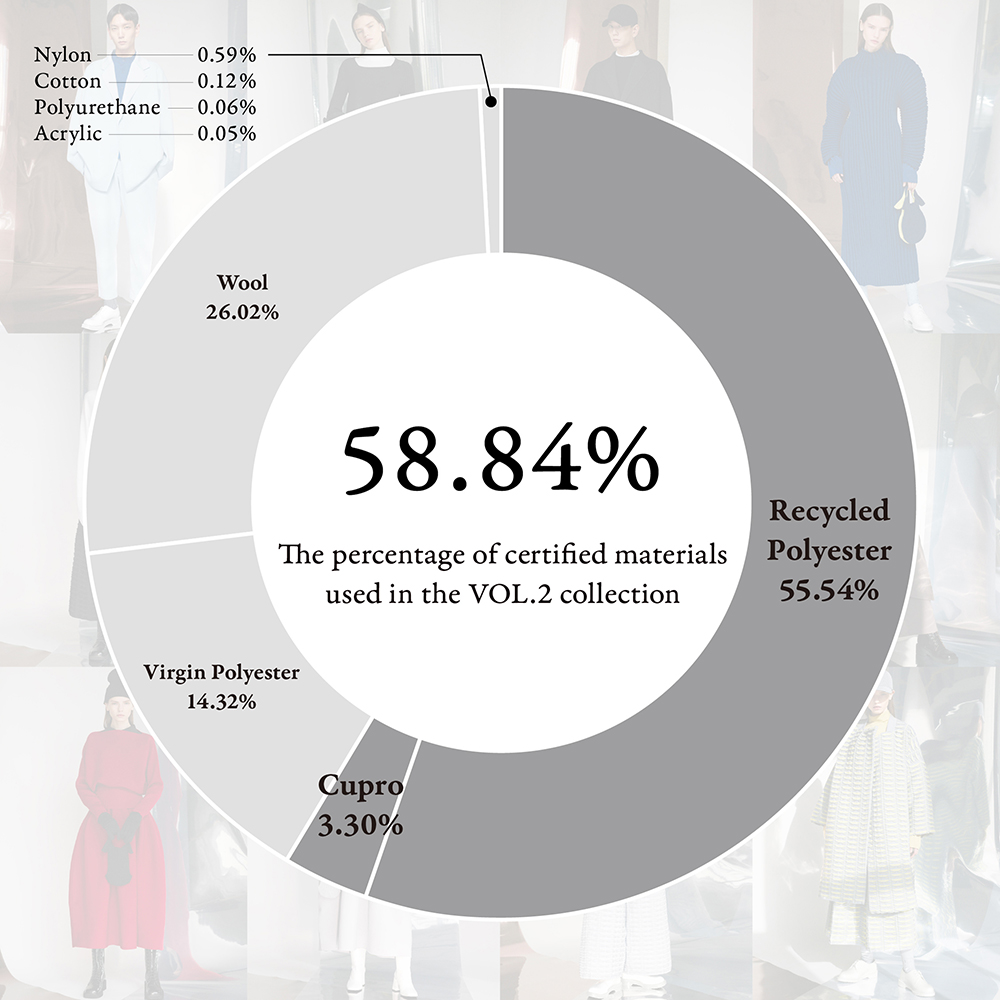

CFCL relies on systems such as the Global Recycling Standard (GRS), to calculate (*) how much materials that meet international standards are used for all our products, including custom-made products. Compared to the 58.12% rate in VOL.1, we saw a slight increase in VOL.2, with a rate of 58.84%.

However, there are still many challenges we face. The polyester, which accounts for about 12% to 14% of the total amount we use, is a petroleum-derived fiber that is not a certified recycled material; a common issue continued from VOL.1. Furthermore, about 26% of the wool we use in VOL.2 is not certified.

Currently, both recycled polyester and recycled wool exist both domestically in Japan and in overseas markets. However, there are still few options currently available, to achieve the “Sophistication”, one of the three major elements of CFCL. Therefore, we chose not to make use of the above materials.

With the support of textile manufacturers in Japan, CFCL will aim to develop and commercialize materials. We will also continue to publish usage rates and encourage the cooperation of our supply-chain, with the goal of producing clothes made of 100% recycled fiber by 2030.

*This calculation does not include accessories such as buttons, zippers, strings, and waist elastics.

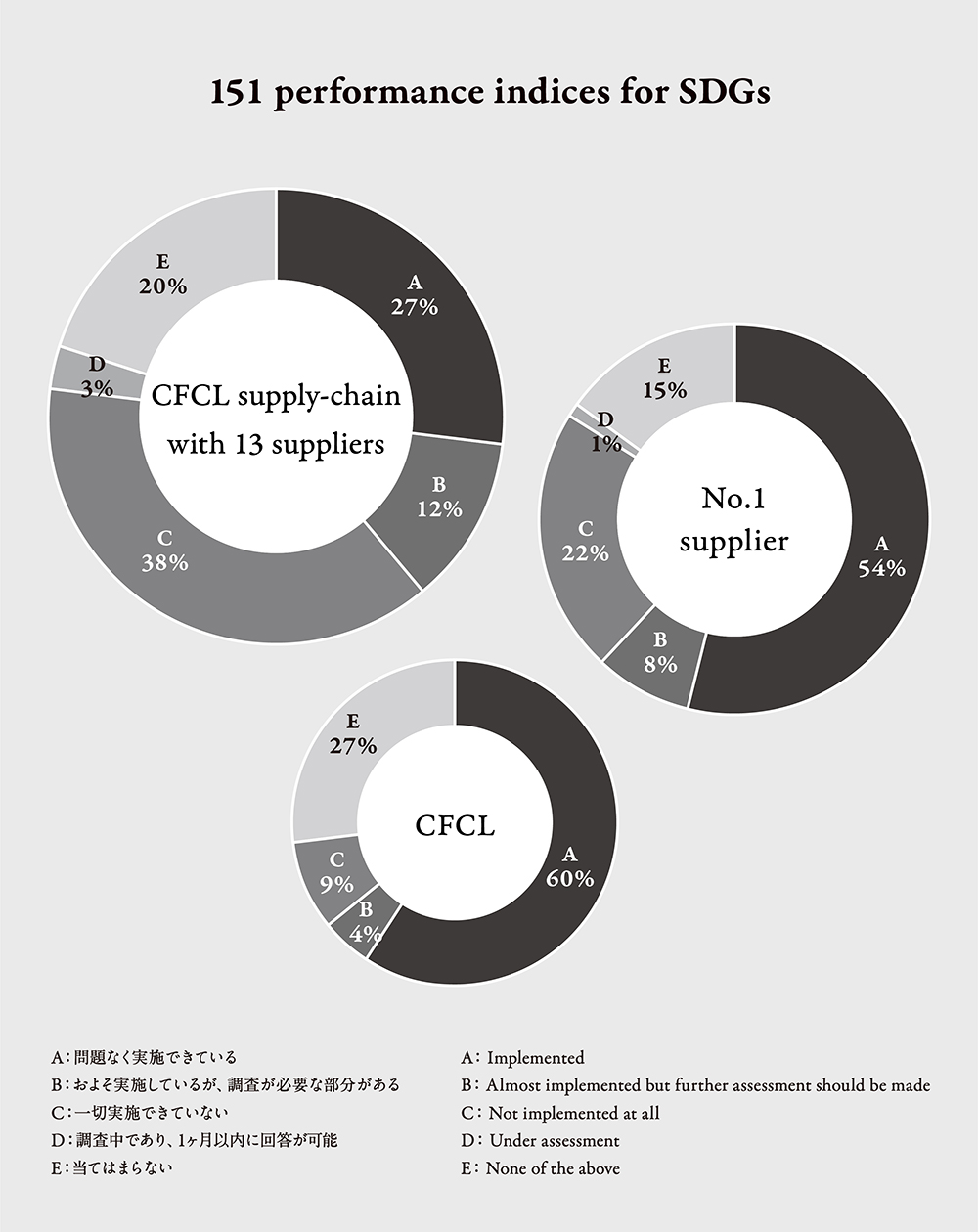

As a new initiative for this season, we conducted a questionnaire on the SDGs Performance Guideline to our manufacturing suppliers. As we are responsible for various activities burdening society and the global environment, CFCL makes it a part of its corporate mission and commitment to providing solutions through our products, business model, and day-to-day operations.

Therefore, to understand what the company is doing and not doing, and to act, we created a list of performance guidelines and started to make assessments.

On the other hand, there is a limit to what we can achieve alone, considering the critical situation in the world regarding the current state of SDGs. In order to truly realize and maximize the impact on our society and the global environment, we believe it is essential to be collaborative and co-create with our suppliers and buyers who create the value chain. To do so, we conducted a questionnaire with them.

① Recovery rate: 86%

② Total number of questions: 151

③ Overall response tendency 1: 39% “A. Can be implemented without problems + B. Almost implemented”

④ Overall response tendency 2: 38% “C. Haven’t been able to implement it.”

⑤ Question example: As the direction and attitude of the company, we understand whether or not we are aware of issues and whether or not we are responding to them.

⑥ Future: In this questionnaire, we are not asking for specific numerical answers for each question. The first priority is to understand ⑤ above. From the next season onward, we hope to work with each company to create a roadmap for improvement, including grasping numerical values.

There are 151 categories that need to be checked within this guideline. Each item is a list to be evaluated and commented on a scale of 5 from A to E. CFCL prepared all content as guidelines for companies to refer to when implementing the SDGs. Although, the contents do not cover all 17 goals and 169 targets of the SDGs, we will further strengthen our future efforts by having each company evaluate themselves together with CFCL.

At CFCL, we believe that working on SGDs is the true value of the company. We will disclose our actual efforts to our customers, ensure transparency, and build relationships of trust with all parties involved. Based on this idea, we aim to be a company that can grow together with society.

CFCL VOL.2 Collection – UPCYCLED FACADE TOP

The item is named FACADE, due to the textures reminiscent of the exterior surface designs of high-rise and apartment buildings. The item features a loose armhole and a silhouette of the sleeves.

We produced the UPCYCLED FACADE TOP using up-cycled yarn so as not to waste the leftover yarn from producing our collection. With a double-layered knitting construction, the front side is knitted in black while the back side is knitted with yellow, light blue, and light gray.