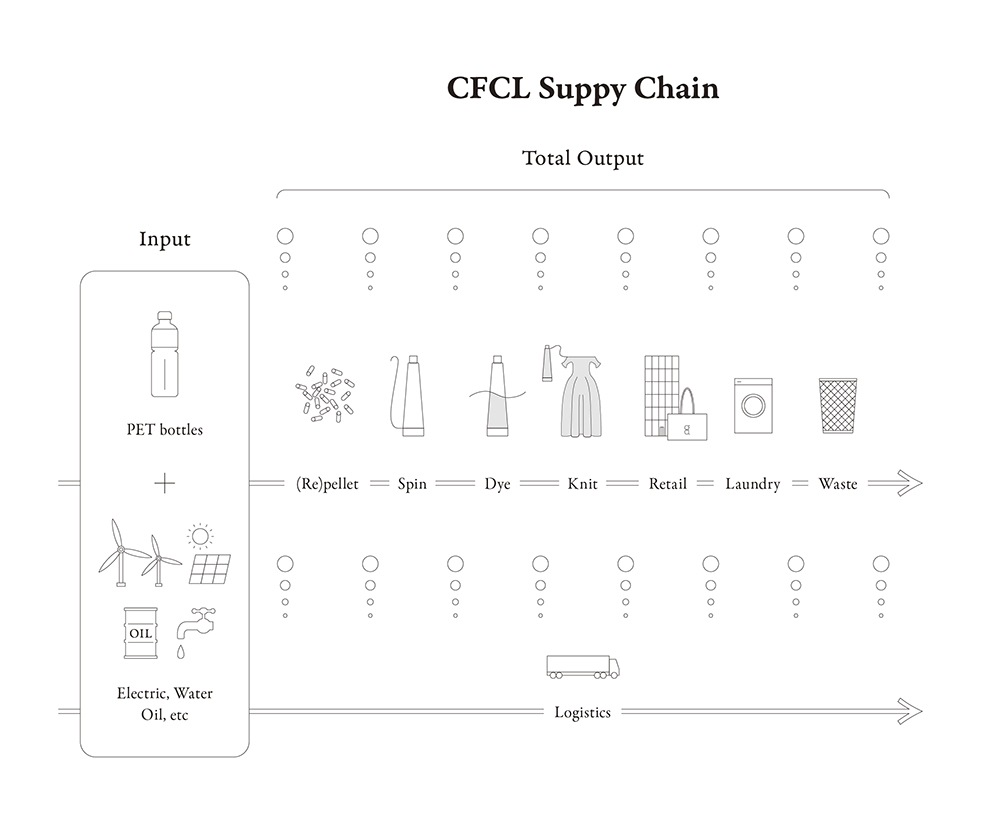

Since its establishment in 2020, the foundation of CFCL’s business has been to pursue the functionality of clothing, while trying to conserve the environment by selecting the most suitable domestic materials and making the supply chain transparent. Through making clothes, we continue to act on what we can do now.

One year has passed since the release of our first collection VOL.1, in January 2021. This CONSCIOUSNESS VOL.3 REPORT includes updates on our progress since VOL.1 and VOL.2, as well as our plans for the future. We disclose such content to you in greater detail, with hopes of connecting to more opportunities for growth.

The following 4 points are the activities and results we carried out through VOL.3.

1. Regarding LCA (Life Cycle Assessment), we widened the range of target items. In addition to the POTTERY series, we expanded to 17 styles including POTTERY KIDS, FLUTED and LATTICE series, which accounts for the calculation of 38% of all CFCL items. From the material procurement process to the final disposal process, we verify the path of “How can we approach carbon neutrality?”

2. The usage rate of materials certified to be responsible for not degrading the global environment and basic human rights increased by 8.22%, and as a result became 66.34% (in comparison to VOL.1).

3. Based on the SDGs Performance Guideline questionnaire conducted in VOL.2, we visited our manufacturing partners, in the Tohoku, Hokuriku, and Kanto regions, spoke about the issues related to SDGs, and started discussions on how to solve them. In this report, we also disclose examples of achievements made by our partner who has produced the POTTERY series from VOL.1.

4. We introduce products that upcycle the remaining yarn from our seasonal items.

Like other advanced countries, the year 2050 is the target for achieving carbon neutrality of greenhouse gas (GHG) emissions for Japan. Additionally, as an interim target for the year 2030, Japan needs to reduce emissions by 46%, when compared to 2013. These goals are difficult to achieve without the fundamental reconsideration of our consumption behaviors and the details of various production activities of companies.

As an approach to achieve this goal, CFCL has continued to carry out LCA (Life Cycle Assessment) since VOL.1.

LCA in VOL.3:

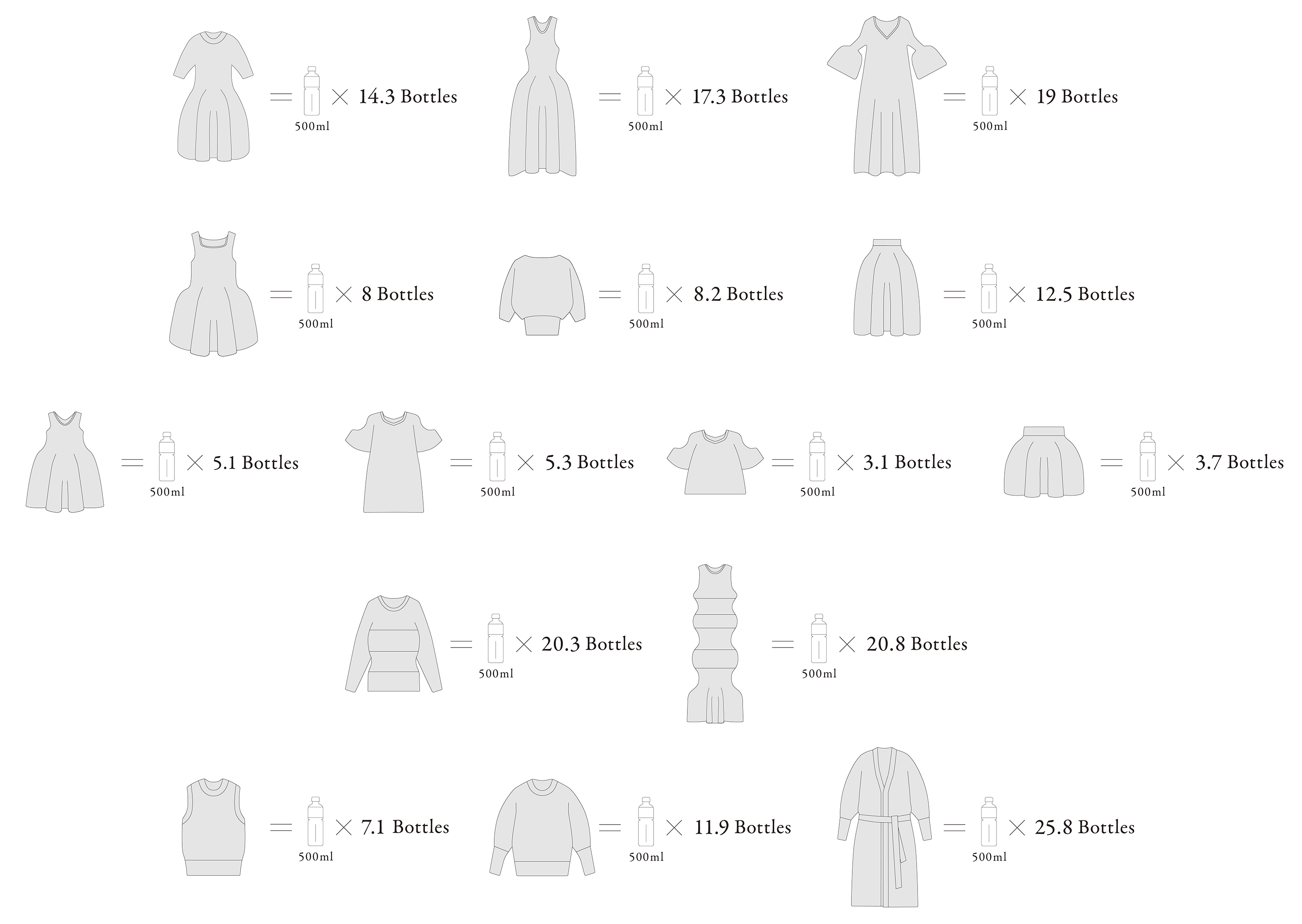

The GHG emissions of the following items are listed in the visuals above:

POTTERY / all 6 styles, POTTERY KIDS /all 4 styles, FLUTED / 2 styles and LATTICE / 3 styles.

In VOL.3, in addition to the iconic POTTERY series (with rounded pot-like silhouettes) and FLUTED series (featuring longitudinal grooves), the LATTICE series (featuring items with a sense of sheerness perfect for spring and summer), have been added to the product lineup, expanding the number of items significantly.

With the cooperation of seven suppliers working with CFCL in Japan, we conducted a verification of “how much is the impact of climate crisis (GHG emissions),” in each series. We observed the entire process from PET bottle collection, manufacturing of recycled yarn, processing and dyeing of yarn, knitting, sewing and finishing, customer use (washing at home), until disposal when the item finishes its role (assuming it incinerated).

Within one year from the launch of VOL.1, we determined the emissions of 17 items (about 38%), out of all 45 styles. (*1)

Our next goal is to announce the results for 100% of our items by 2025.

*The visuals above, indicate the approximate number of PET bottles used per piece of item.

Assessment by Product:

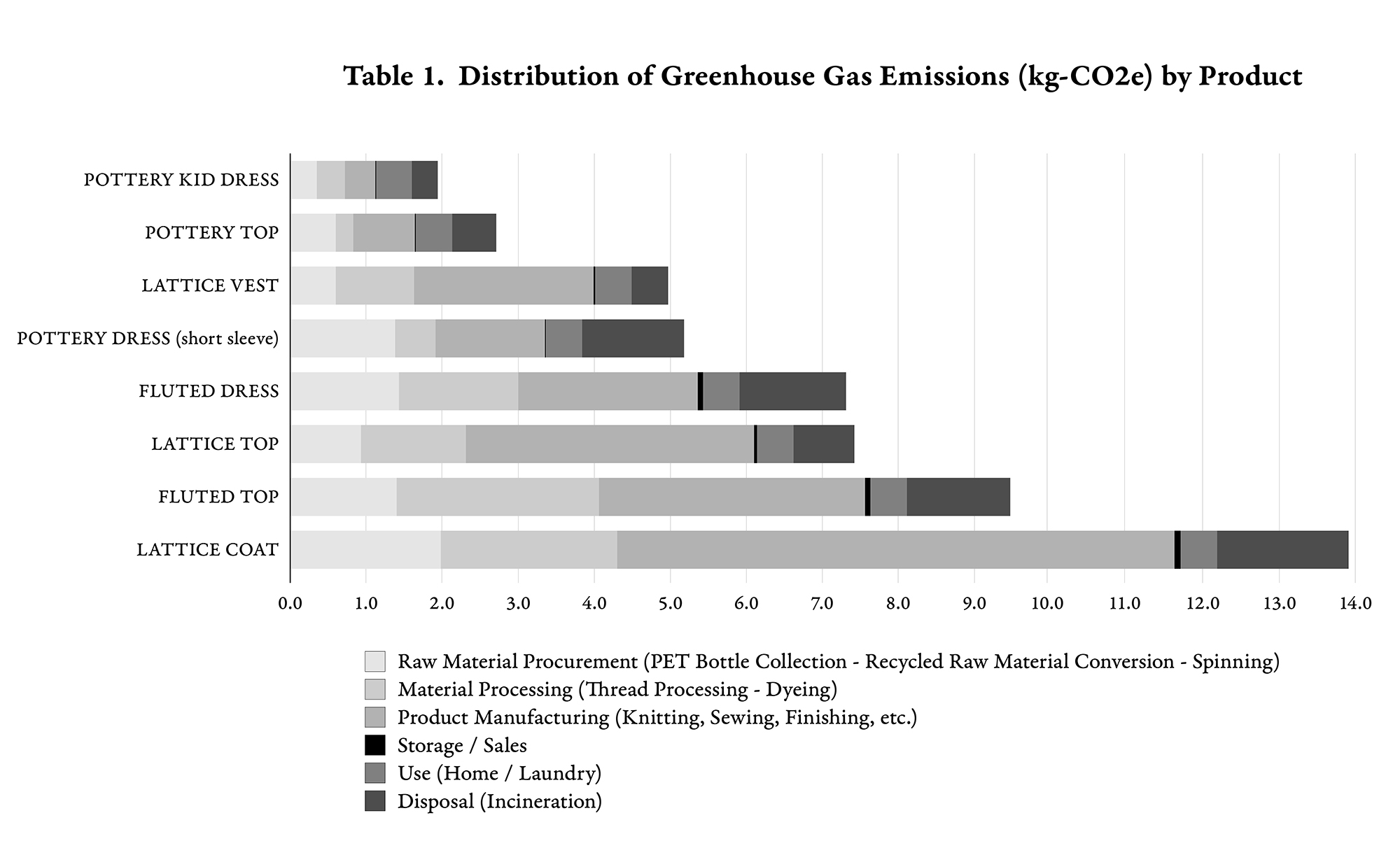

As a result of working on this matter for the past year, we have found “how much GHG is emitted from the way of production at our partners’ manufacturing facilities, the materials we chose, and the way customers use and dispose of our items” (e.g., POTTERY DRESS short sleeve 4.99 kg-CO2e).

However, the true purpose of implementing and publicizing this LCA is to think about how to reduce such emissions (how to avoid the climate crisis and take responsibility for the next generation), as well as to think about the path and to put it into practice.

Therefore, in this report, we would like to introduce the assessment results in detail: results of each item, in what situation (process), how much emission, and how much it can be reduced. The results are shown in Table 1 below.

LATTICE long coat, which first appeared in VOL.3, has the highest GHG emissions, while items from POTTERY KIDS series has the minimum number of emissions. Although there are several elements involved for this result, as listed below, there are three main factors we can raise.

1. The large amount of yarn usage

2. Whether the item is a seamless knit

3. The complexity of the knit design

Since the texturized and expressive designs of the FLUTED and LATTICE series require multiple sewing and ironing finishes, they emit more GHG than the POTTERY series. With a minimalistic design and production approach, CFCL minimizes the logo size, selects materials and combines the structures of clothes in the simplest way. However, the amount of yarn and emissions are substantial, because the long coat is the largest and longest in size among the items evaluated by LCA.

For CFCL, these series are important for continuing our creative challenges. Therefore, without discontinuing such items, we would like to pursue ways to evolve, so that our clothes can be completed with one yarn, while reducing the amount of emissions. While realizing expressive, delicate, and detailed knit designs, we propose five measures in order to achieve carbon neutrality.

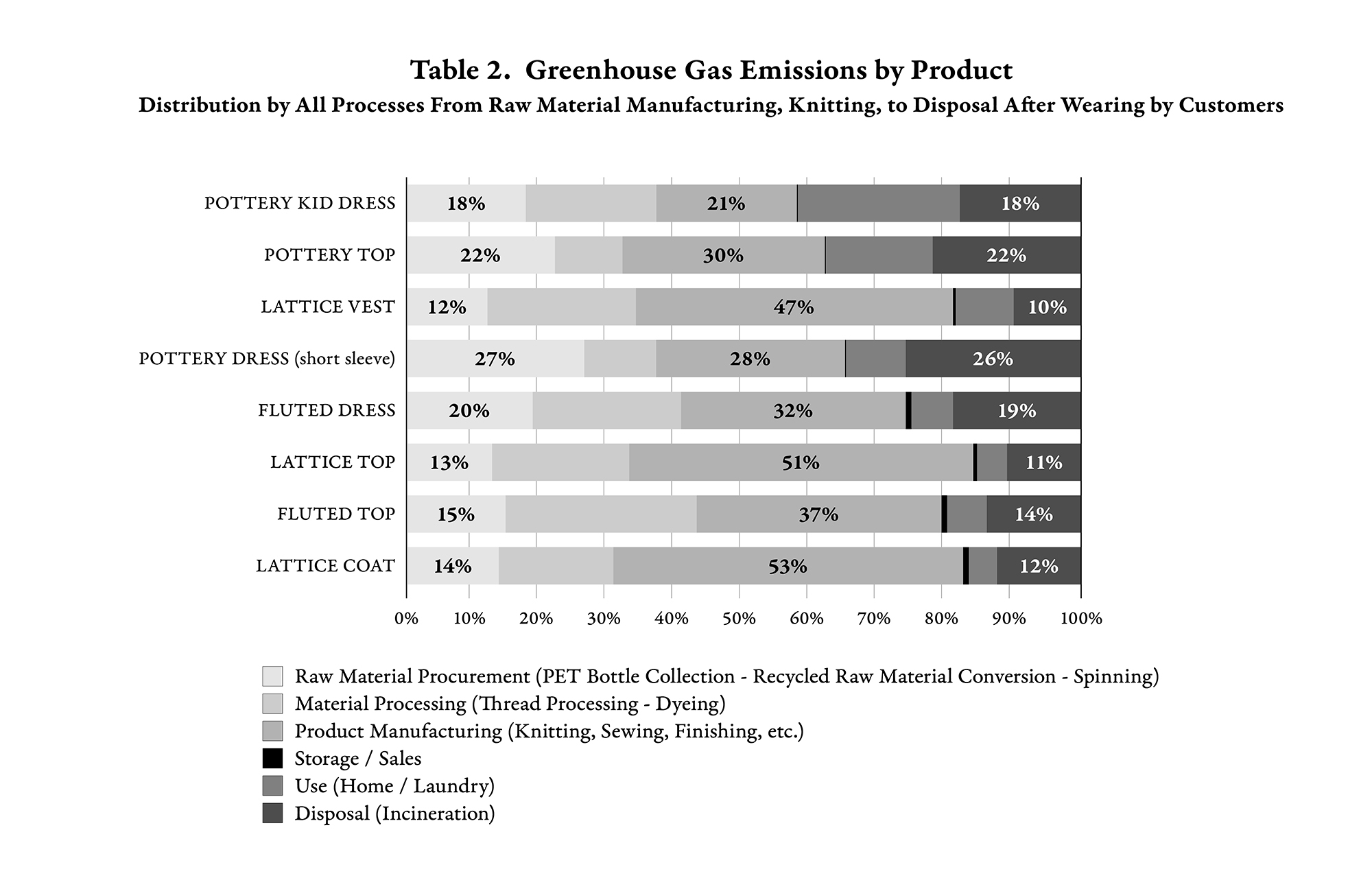

Table 2 below, is an analysis of the Table 1 from a different perspective.

■Measure 1: Promote the shift to renewable energy at our partners’ knit manufacturing facilities

■Measure 2: Promote energy-saving designs, such as for knit manufacturing equipment

When compared to other processes, the ratio of GHG emissions is generally higher in the manufacturing process of items, such as knitting, sewing, and finishing. As a knit brand, CFCL cooperates with our knit manufacturing partners in Japan regarding this manufacturing processes of items to pursue sustainability, such as switching to renewable energy and exploring possibilities of energy-saving designs for equipment. (Specific examples of improvement are described in the SDGs Performance Guideline segment we cover in the latter half of this report.)

■Measure 3: Shift raw material to other material that further reduces the environmental burden

■Measure 4: Promote the shift to renewable energy at raw material processes

Next, we found that the second highest ratio of GHG emissions, is in the process of procuring raw materials: collecting PET bottles, producing recycled raw materials, and spinning. CFCL already uses recycled raw materials (recycled polyester, recycled cotton, etc.), for about 70% of the total items in VOL.3.

As a result, we have achieved a GHG reduction of about 50% (*2, *3), compared to virgin polyester and non-organic cotton that are newly procured by oil drilling. However, in the future, we aim to achieve carbon neutrality by continuing discussions with raw material manufacturers, devising procurement sites and raw material processes, and shifting to renewable energy centered on solar and wind power.

■Measure 5: Avoid disposal

The amount of GHG generated in the process where the item is thrown away by consumers after use and transported to incinerators for final disposal, tends to be next in line as the third largest ratio of emissions.

At CFCL, we strive to undertake short and long-term challenges and listen to the voices of our customers daily, in hopes that the clothes can be worn for a long period of time, without changing the trend significantly for each season. In the short-term, the challenge we face is to achieve the design and quality that does not produce waste, as well as figure out ways for repair. On the other hand, our long-term challenge is to promote manufacturing with the same unified material, to recycle discarded clothes into yarn with “chemical recycling” in the future.

CFCL aims to cover all items with LCA by 2025, by working on such factors mentioned afore. Furthermore, by practicing decarbonization and minimum waste daily, we aim to achieve carbon neutrality and to solve social issues stated in the SDGs by 2030.

*1: Calculated using IDEA v2.3. (LCI Database IDEA Version 2.3, Japanese National Research and Development Agency, Advanced industrial Science and Technology, The Research Institute of Science for Safety and Sustainability and LCA Research Group, Sustainable Management Promotion Organization)

*2: In-house research

*3: “Analysis of inventory of CO2 and water intended for clothes” – Norihiro Itsubo Laboratory, Department of Environmental Studies, Tokyo City University

66.34%

For the VOL.3 collection, the usage rate of production raw materials certified as responsible for not degrading the global environment and basic human rights is “66.34%” (Table 3). Compared to VOL.1 (categorized in the same spring summer season), we were able to improve by about 8.22%.

There are several factors involved in the selection process of raw materials and other materials for CFCL. The main points are that the core is recycled material, and the human rights of the production site are protected, (going back to the raw material stage). Whether it is a material or product, a newly developed material or biomass material, the one-way flow of disposal after use is directly linked to the emission of GHG that cause the climate crisis. Therefore, we believe it important to recycle.

Avoiding disposal and encouraging recycling will lead to the formation of a “circular society,” if thoroughly implemented in all industries. However, even in a time where the term recycled material is no longer rare, looking at the global apparel industry, the percentage of recycled materials used is less than 5%, compared to virgin materials that are newly mined, logged, and collected. (Reference: Ellen MacArthur Foundation. A New Textiles Economy)

CFCL thoroughly implements the process of “Recycle” represented by the 3Rs (which stands for Reduce, Reuse, and Recycle), by actively using recycled materials to reduce the use of new global resources. Even with the increasing number of products and amount of yarn usage, we will promote the conservation of resources by increasing the usage rate of recycled materials.

As a result of these efforts, the increase in the use of recycled material (compared to VOL.1), can be confirmed in Table 4 below.

*Although the amount of cotton used is a mere 2% of all items, 90% of the cotton used is OCS certified.

*The above total does not include accessories such as buttons, zippers, strings, and waist rubber, since the usage ratio in CFCL items is small.

SDGs Performance Guideline:

In order to solve the problems surrounding the SDGs, we concluded that working on the entire value chain in relation to CFCL, can produce a wider and more immediate impact. As partially reported in the CONSCIOUSNESS VOL.2 REPORT, as a new initiative, CFCL conducted a questionnaire on the SDGs Performance Guideline in August of 2021 and confirmed the actual status of activities in the SDGs with 13 of our manufacturing suppliers.

After the questionnaire, we physically visited their sites one by one, and directly discussed the responses we initially received from the companies, as well as possible improvement measures.

Out of 13 manufacturing suppliers, we would like to focus on one partner (residing in the Kanto area), that has been producing the POTTERY series from VOL.1. We will introduce what kind of questions and measures were taken (based on the SDGs Performance Guideline), regarding the improvement in production management of this partner.

Question: Do your key products and services reduce the amount of waste in the entire company, and can this be verified with your annual total figures?

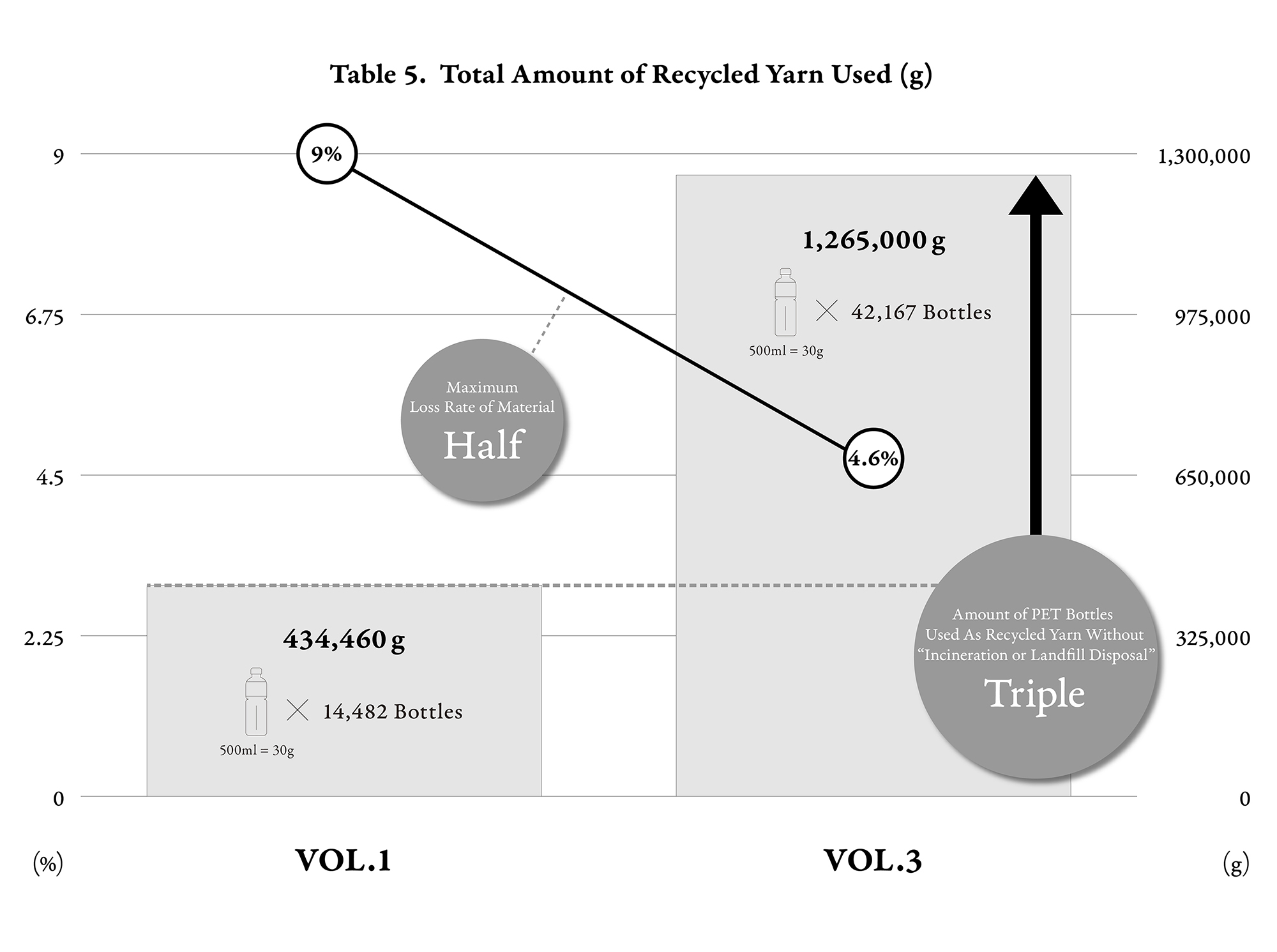

Response: By improving the knitting operation, the 7-9% loss rate (*) in VOL.1 has been reduced to 4-5% in VOL.3. The amount of yarn discarded due to “production loss” including the occurrence of defective products is reduced. (Table 5)

“Triple”: Amount of PET bottles recycled as yarn, without being incinerated (thermal recovery)

“42,167 Bottles”: Converted number of PET bottles used as recycled yarn (VOL.1 was 14,482 bottles)

“Half”: Loss rate of materials that had to be discarded due to defects in the production process

As mentioned above, continuing to design the POTTERY series (which is not significantly influenced by trends), has resulted in higher production accuracy and efficiency for our partners. This has also led to a reduction in the loss rate.

(*Loss rate: The ratio of defective products and unnecessary parts produced, when items cannot be knitted as designed and must be stopped in the middle of production. Also, refers to the ratio of waste materials, such as yarn generated as a result of the production process, mentioned above.)

Question: Do your company’s key products and services help reduce new use of global resources, and can this be verified with your annual contribution figures?

Response: In January 2022, we switched to using renewable energy for our manufacturing facility and equipment.

– Before January 2022: Approximately 80% of energy such as coal and gas, was generated by thermal power generation.

– From January 2022: “100% renewable energy” centered on solar and wind power → Zero impact on climate crisis

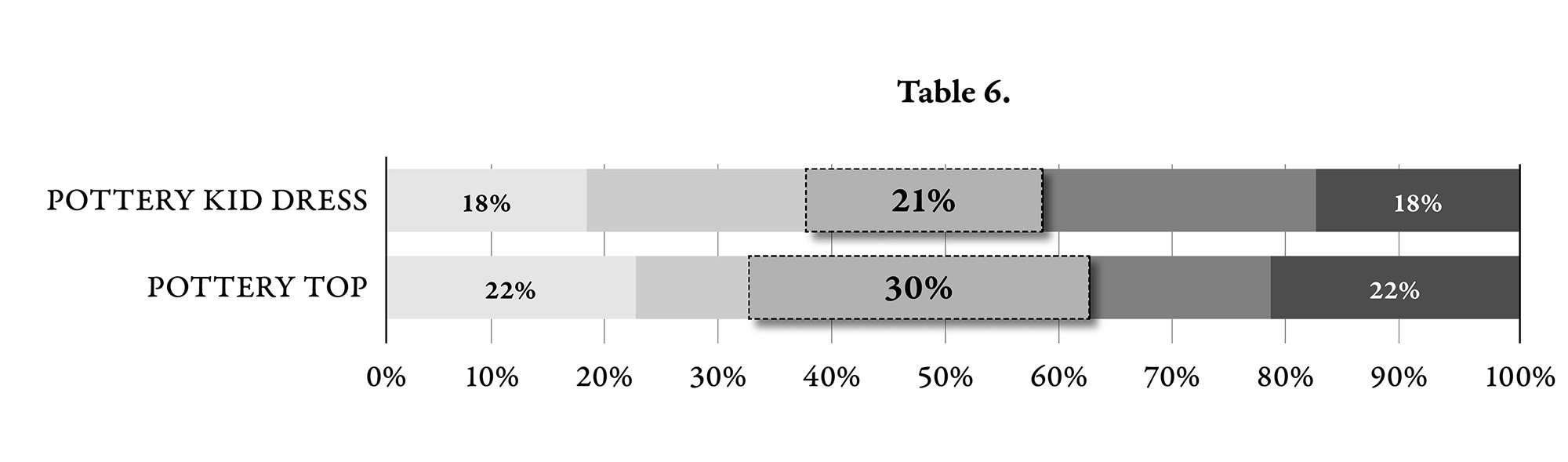

As a result, GHG emissions will be reduced by up to 30% for all CFCL POTTERY series items, from the release of VOL.4 the summer in 2022. (Table 6: Highlights the POTTERY series, with the excerpt from Table 2)

The Future SDGs Performance Guideline:

As an initiative of our future performance guideline, we will discuss with each company how CFCL can contribute to various stakeholders such as suppliers and partners with whom CFCL is directly and indirectly related to (not limited to the manufacturers).

The stakeholders we consider can be broadly divided into four categories:

1. Global environment

2. The local community in which the company, supply chain, and partners operate

3. Company employees

4. Customers and consumers

Throughout our activities, while obtaining financial and non-financial benefits, determining what kind of places, people, problems and challenges can generate benefits, as well as clarifying how best to check our achievements, are quite difficult to do solely by CFCL. However, “local community” mentioned in point 2 can act as a hint.

Our employees are also connected to the local community through their hometowns. Therefore, the following questions become important as we continue discussions.

1. What exactly is the local community for your company?

2. If the business with CFCL expands and can bring benefits not only to your company but also to the community, what kind of situations, people, problems and challenges are they?

3. Along with financial achievements such as sales and profits, what are the indicators that should be checked in the long-term as an outcome of your business results?

These questions may sound unprecedented, especially as the core of business. However, in anticipation of the SDGs, these are indispensable questions to have every single employer and employee take ownership and challenge every obstacle that stands in the way of achieving the SDGs.

By continuing discussions with each company, we would like to share the results of our efforts with these stakeholders, through the CONSCIOUSNESS REPORT.

CFCL VOL.3 Collection – UPCYCLED POTTERY SKIRT

Our iconic POTTERY series has a symbolic rounded silhouette like a pot.

In VOL.3, we introduced the UPCYCLED POTTERY SKIRT using upcycled yarn so as not to waste the leftover yarn, originally prepared to minimize the color blur during mass production. The items are available in 9 vibrant colors.