CFCL was accredited on July 28, 2022 as a “B Corporation”, a world-renowned international certification. Since our establishment in 2020, we have been pursuing the functionality of our clothing while at the same time attempting to preserve the social and environment. We are very pleased to have received this prestigious third-party certification for our effort to select domestic materials, for putting transparency of the supply chain as a central corner stone of our business, for clothing production to create benefits within all communities including local communities, society and our business partners, and for building a business model and governance that will help realize the 17 SDGs on a global scale. This CONSCIOUSNESS REPORT is aimed at providing an even more diverse and substantial contents and to serve as a forum for comments and guidance.

In this report, we are addressing CFCL’s new initiative of starting to move forward from “Analysis and Assessment” to “Improvement and Implementation”.

The following four items summarize the activities and results we have conducted through VOL. 4.

1. LCA (Life Cycle Assessment)

1-1. LCA has continued since VOL. 1 with VOL. 4 showing the results of product assessment

1-2. As previously announced in the VOL. 3 report, this report will show our efforts and results in the reduction of carbon footprint

2. Procurement of Materials

Regarding our efforts to use more materials that are certified as being responsible for the global environment and basic human rights

3. Creating Benefits for the Community

Regarding the mutual efforts based on our SDGs Performance Guideline and LCA implementation conducted in VOL. 2 through our cooperative relationship with our business partners in Japan, including manufacturing factories and trading companies

4. Product

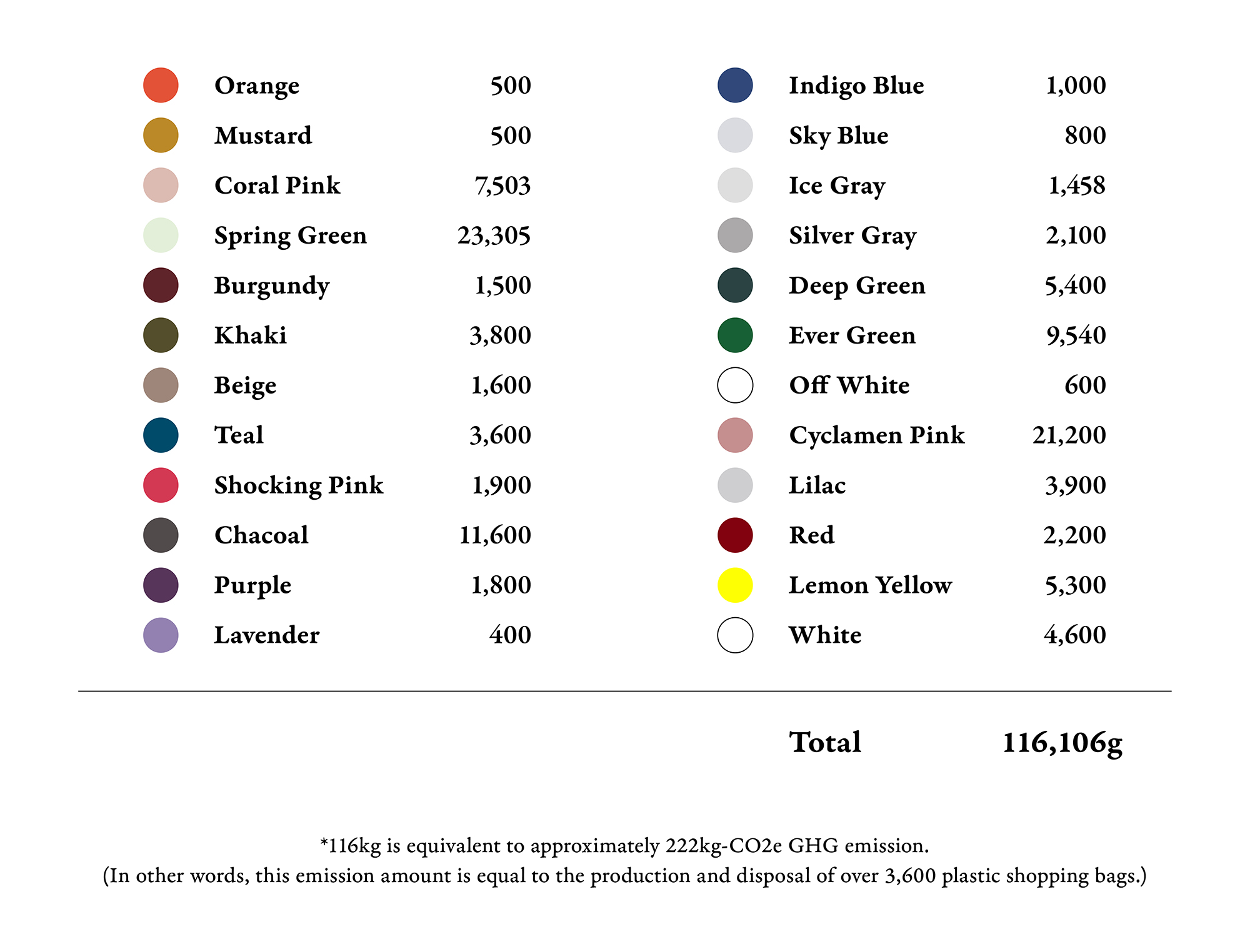

Regarding destination of 116 kg of remaining yarns

There are two main points in VOL. 4.

Point 1:

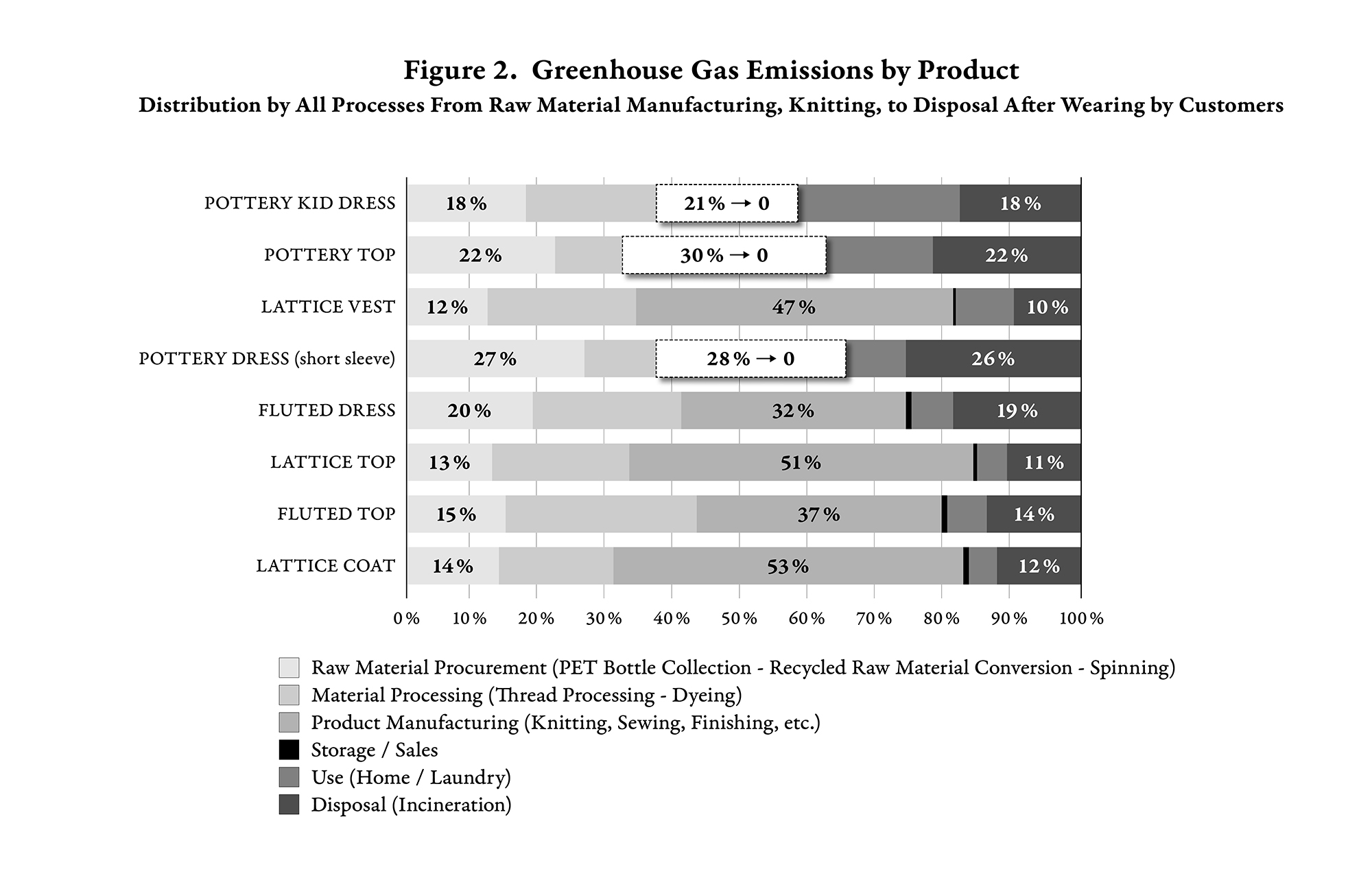

The product lineup of a total of 45 styles at the time of VOL. 3, has increased by 2.5 times to 111 models in total for VOL. 4. LCA was performed on a total of 45 styles from five series of products. Led by the POTTERY series, which has been well received by many customers since VOL.1, calculations and assessments of greenhouse gas (GHG) emissions were conducted for all manufacturing and consumption processes.

Point 2:

Based on the results of the past year’s assessment, VOL. 4 POTTERY series are being produced in a way that actually reduces GHG emissions. We have reduced them by up to 30% through close cooperation with the factories and energy companies located close to the CFCL headquarter in Tokyo and peripheral areas.

The following is a detailed report on the results of these two activities.

Products covered in VOL.4:

POTTERY. 22 styles in total (including GLITTER series with recycled lamé yarn, nearly tripling in number from VOL. 3)

POTTERY KIDS. 16 styles in total (Joyful matching designs for kids and parents,; expanded 4 times from VOL. 3) FLUTED. 3 styles (the second most popular series after the POTTERY series, with a 1.5 times increase from VOL. 3)

STRATUM. 3 styles (A new series, characterized by a fine horizontal groove texture reminiscent of geological strata and a unique balloon-like form)

LOW GAUGE TOP. 1 style (A new series, soft and voluminous, and comfortable to wear, featuring a complex knitting structure that looks like small window openings)

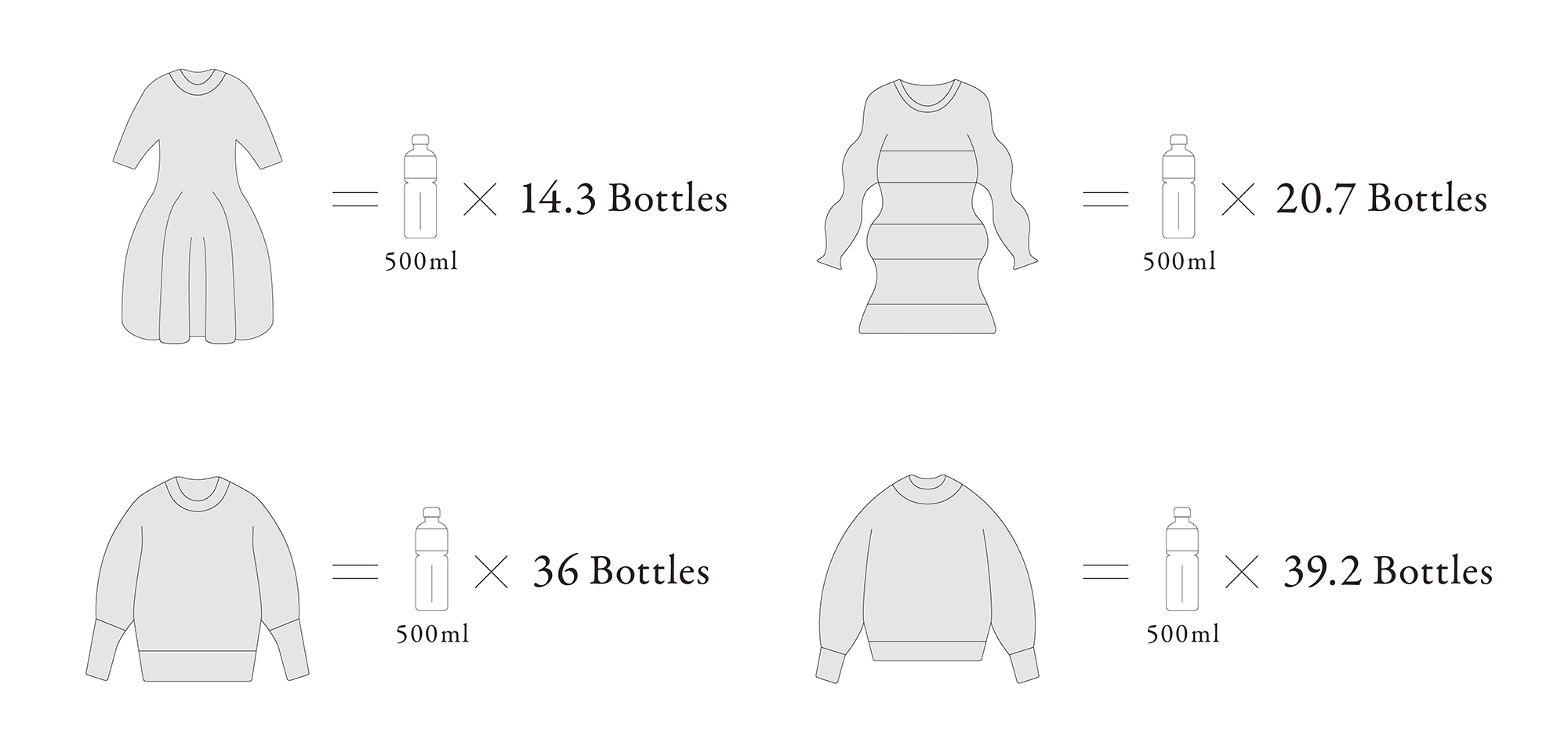

In 45 of the 111 styles of product, or about 40% of the total, we know the amount of GHG emissions that CFCL will have to reduce in the future. We have picked out each product series and show the actual kg-CO2e in a picture below. All products for which assessment have been completed is now posted individually on our online store.

The number of products for which LCA work must be performed has increased 2.5 times since VOL. 3, but the scope has also been expanded from that of VOL. 3 for assessment. We are conducting LCA on nearly half of all our products for the 12th SDG target “Responsible Consumption and Production” and the 13th SDG target “Climate Action”.

Future Issues:

As a company that is still small in scale, CFCL has continued to work on LCA since its establishment, and as a result there is an issue that we have become aware of. The information required for LCA of some parts, both in Japan and overseas, is rarely shared among the entire supply chain. This is a problem that makes it difficult to quantify results.

CFCL indicates in VOL. 4 that “zippers and buttons” are examples that are used in about 20 styles or about 18% of the total. We have not yet been able to determine appropriate the impact of GHG emission per garment for products with these components, and as a result have not been able to logically move forward with decarbonization efforts and discussions to decarbonize the industry. As long as this problem exists, CFCL will not be able to achieve its goal of “implementing LCA on all products” and achieve specific initiatives by 2025.

However, CFCL is actively taking responsive action. We hope that our activities will help accelerate global warming initiatives in more companies, as the quantification of information will be useful to both domestic and overseas companies in similar and different industries. This is based on the concept of “Capitalism as a B Corp,” which creates benefits more widely through co-creation, rather than just from the conventional capitalist perspective of competition and rivalry.

The activities already underway are summarized in the following three points.

1. Hold discussions with each manufacturer of the subject parts and carefully check the necessary information for LCA.

2. Examine measures in consultation and cooperation with relevant policy makers, such as the Ministry of the Environment, the Ministry of Economy, Trade and Industry, other ministries and agencies.

3. Study measures to be taken through exchange of opinions with other B Corp certified companies around the world and through collaboration with other companies in the same or different industries.

We will continue to share our progress with you in our CONSCIOUSNESS REPORT.

The POTTERY series has reduced its GHG emissions by 30%

January 2021 VOL. 1 “POTTERY DRESS short sleeves” 4.99 kg-CO2e

July 2022 VOL. 4 “POTTERY DRESS short sleeves” 3.49 kg-CO2e (equates to a 30.1% reduction) (*1)

The approximate amount of GHG emissions per ordinary garment is 25.5 kg-CO2e (*2)

A year and a half after the release of the first POTTERY series, this series has gradually expanded styles, resulting in this VOL. 4 release. In the meantime, we have been in meticulous communication with CFCL’s partner knitting factories in Tokyo and peripheral areas, which has resulted in the switch to renewable energy sources, mainly solar and wind power, for electricity to run production facilities. All 38 styles of the POTTERY series in VOL. 4, which went on sale in July 2022, were produced with up to 30% less GHG emissions than ever in the past. (*3)

All future POTTERY series will be made in this low carbon emission production environment.

As a result, as of mid-September 2022, the total amount of GHG emissions reduced in all production was approximately 4.3 tons. To give you a rough idea of the impact of this reduction, it is equivalent to the amount of emission from a gasoline-powered car traveling “about halfway around the globe” (*4)

As shown in the figure below, which was reported in detail in the VOL. 3 report, the true purpose of conducting and publicizing LCA result is to communicate how we can reduce these emissions (how we can prevent the further climate crisis and fulfill our responsibility to future generations). It is to show the basis and details of our efforts in a transparent and continuous manner over the long term so as to achieve carbon neutrality. As a B Corp, CFCL is committed to this responsibility.

(Ref. VOL.3 LCA Assessment by product “Measure 1. Promote the shift to renewable energy at our partners/ knit manufacturing facilities)

*1 Calculated using IDEAv2.3 (LCI database IDEA version2.3, National Institute of Advanced Industrial Science and Technology Research Institute of Science for Safety and Sustainability, Sustainable Management Promotion Organization, , LCA Research Group Safety Science Research Division,)

*2 Ref.: The Ministry of the Environment of Japan

*3 Mainly solar and wind power generated domestically; like many Japanese companies energy up to VOL. 3 was energy generated by coal-fired power plants.

*4 Condition: A gasoline-powered car with a fuel efficiency of 10km/L driven the distance approximately 20k km.

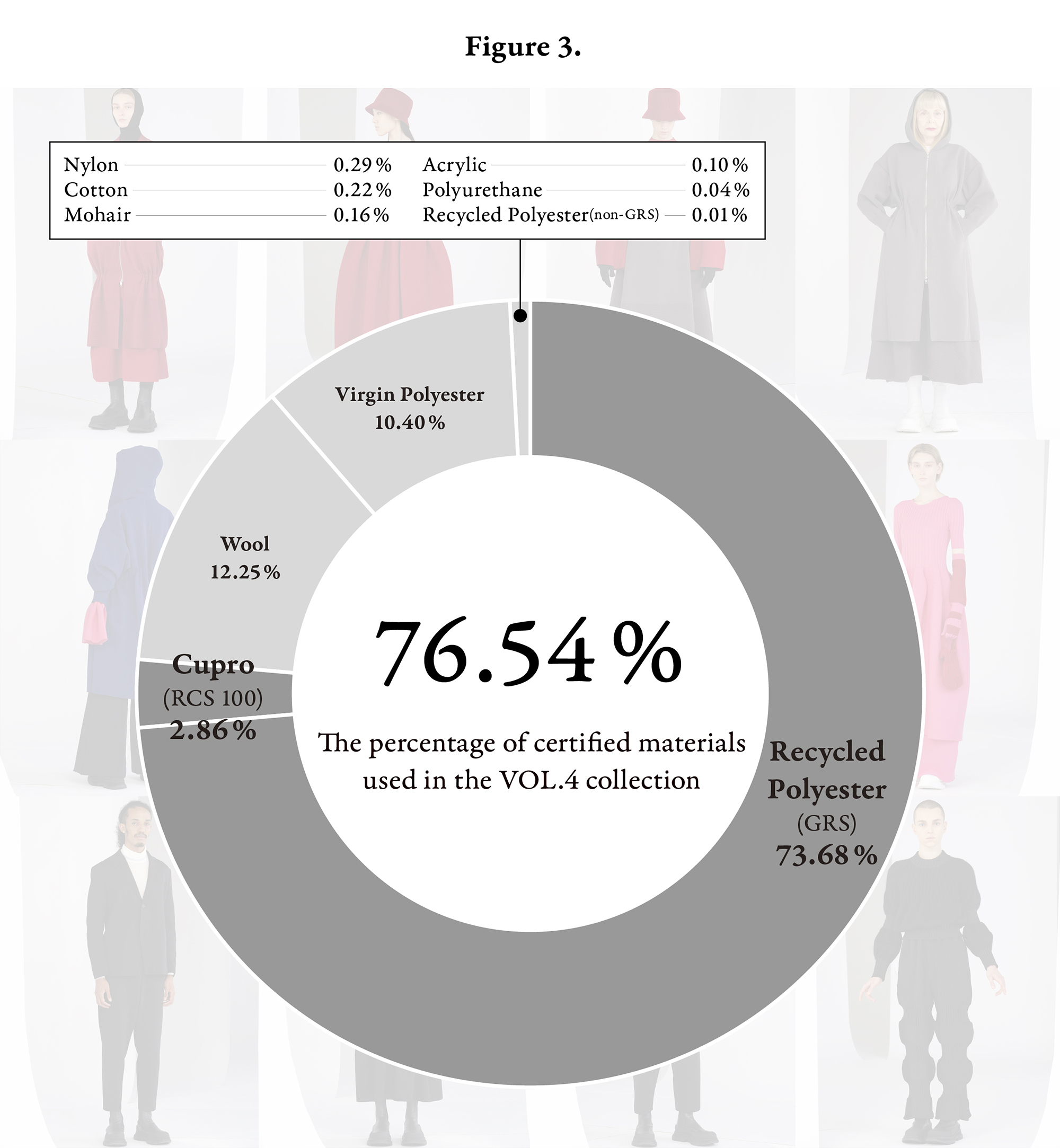

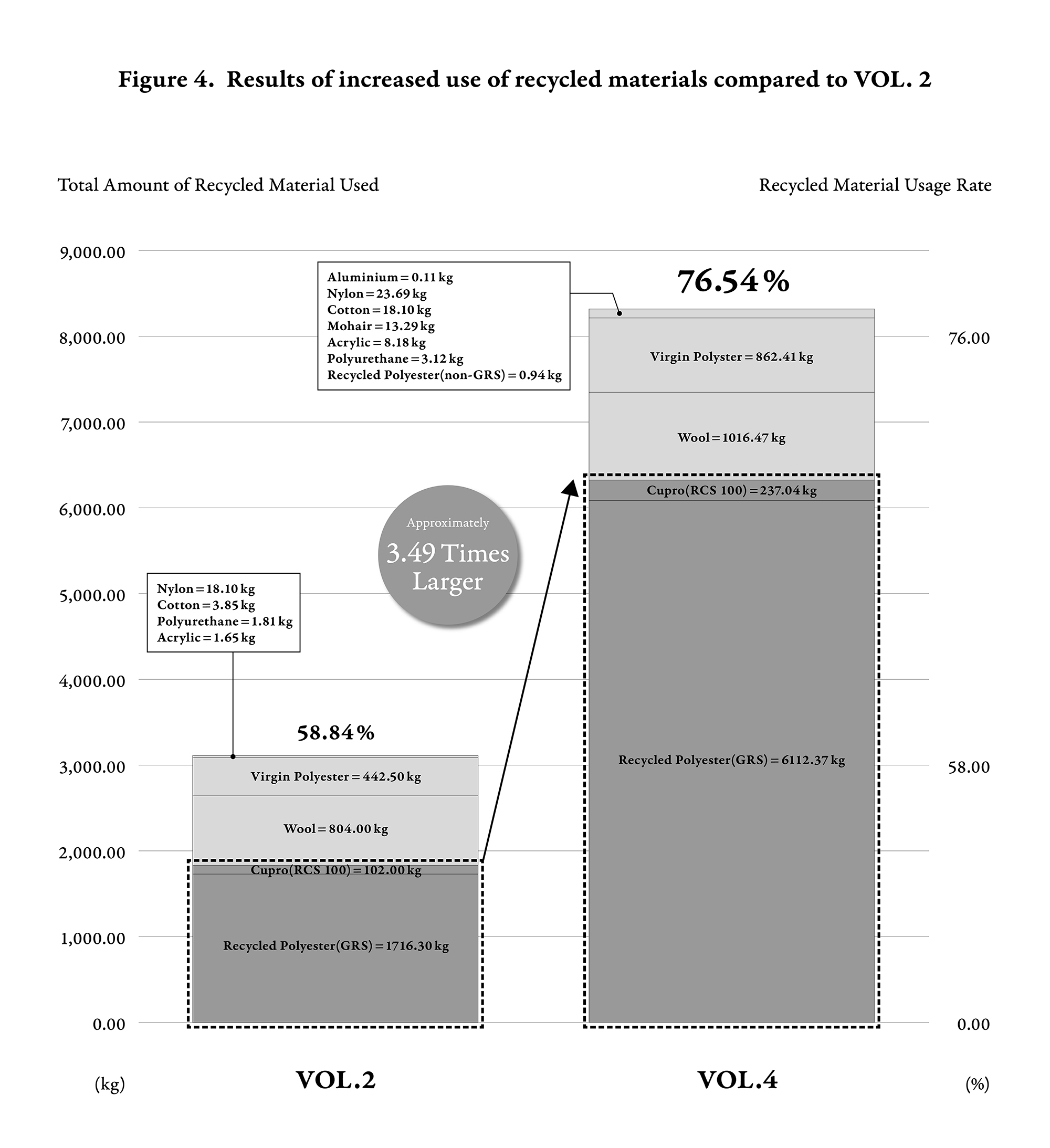

[ 76.54% ]

This figure shows the main materials used in the mass production of the VOL. 4 collection were positive contributors to the global environment and basic human rights and this figure has been certified by a third party organization. As a result, the majority of products (more than 70% of the total) actively use these materials, approximately 18% more than in VOL.2 of the previous fall/winter season. This number is the highest of any of our previous collections.

Three reasons are as follows:

1. We operate with our own policy in the “procurement and purchasing” of all materials, sub-materials, and equipments. One is the active use of recycled materials which is reflected in the figures and is a result of the daily practice of this policy in our employees’ decision-making process.

2. All employees, from the planning and design stages, are involved in the review of the material composition of all products resulting in the increase of the amount of recycled materials used with each increase in product type and quantity.

3. Know-how of recycled materials is being accumulated in the textile industry. Among plastics (synthetic fibers), especially in polyester, the production process of raw materials, machinery and equipment have driven the evolution of the industry’s benchmark, resulting in the stability and improvement of the basic level of quality. A dramatic increase in proposals from our domestic suppliers compared to VOL.1, our first collection, has resulted and the number of options available to CFCL has increased proportionally with this.

Ongoing issue:

As discussed in VOL. 2, the issue of the use of non-recyclable materials and wool which is not subject to certification still remain. In VOL. 4, these materials were used in approximately 12.28% of the total. We are working with multiple domestic suppliers to develop solutions and high quality recycled wool yarn while conducting LCA within the next two years and bring products to market.

These activities drive the formation of a “circular society” by utilizing high literacy and common sense of our local communities and domestic supply chain partners.

*Buttons, zippers, ties, elastic waistbands, etc. are not included in the above totals due to the small percentage used in CFCL products.

(Ref.) Recycled Claim Standard (RCS) and Global Recycle Standard (GRS) – Textile Exchange

The Impact CFCL Creates in the “Community”: Actions and Influence to Build a Sustainable Society

Previous CONSCIOUSNESS REPORTs have mainly reported on CFCL’s activities centering on the pressing issue of global warming countermeasures, but there are many issues other than global warming that we, as companies, need to take action on. Such issues as human rights, social diversity, equality, inclusion, gender gap, economic disparity, and the 17 Goals of the SDGs, must be addressed. Since the scale of these issues cannot be resolved by the efforts of a single company, it is imperative that all supply chains that make up manufacturing and service production cooperate with each other, regardless of the industry. To this end, CFCL has formulated our “SDGs Performance Guideline”, and is promoting efforts to make step by step improvements by sharing with our business partners the 151 specific daily life and work perspective items of this guideline.

The chart on the above shows the score for impact on the community (local community, a specific industry or group of people), reviewed for B Corp certification.*5 The score is 32.1 out of the full score of 70. While the overall score is high at 128 points, it indicates that many issues, such as community, still need to be addressed.

To a Tokyo-based business, what does “community” mean to CFCL? If there are communities with social problems, identifying that community which we can benefit, through our daily business activity, is key to management that creates impact.

CFCL’s production base in local Japan, is an industry in need of economic revitalization. We believe that the “local textile industry,” which is in the middle of the supply chain, has employment and income issues stemming from a declining birthrate, aging population and business succession, can be the community to focus on. We have taken the time to increase our relationships with them utilizing the “SDGs Performance Guideline”.

June 2022 Seminar for Three Hokuriku Area Manufacturing Partners:

CFCL initiated lectures in June 2022, which planning was started in February of the same year, to four historical companies in thread processing and dyeing technology, and that have been our business partners since VOL 1. These included lectures on B Corp (a global benchmark for SDG implementation), the history and background of the SDGs, and issues in our apparel industry, which is considered the second most global polluting industry. The event also provided an opportunity to learn from each other and to share issues and potentials that we should challenge as an industry in the future. LCA is a tool that can show not only GHG emitted from respective supply chain processes, but also display chemical and wastewater, water conservation, exhaust and disposal. Through the technologies and knowledge that each factory has developed during the past 50 plus years, proposals are being created to solve future issues. We believe that Japan, with its supply chain as its base, has the potential to make great future strides in the SDGs by communicating to the world about fashion and the B Corp community. We will continue to work on this so that we can report back to you in the form of specific figures and products.

This joint event was originally planned as part of an induction training program for a company in Ishikawa Prefecture following the hiring of two new employees in April of this year. This local company had not had a new employee for a long time because of chronic problems, such as low-income. As a result, the seminar was attended by about 20 people, including management and new employees from four affiliated companies. We will continue to build a relationship of trust with the community through similar initiatives and create a business model through partnership that enables us to solve additional issues.

*5 Data that can be viewed at any time on B Corp’s official website(https://www.bcorporation.net/en-us/find-a-b-corp/company/cfcl-inc)

From this CONSCIOUSNESS REPORT on, topics of interest will be presented under this title PRODUCT. The topic we will cover in this report will be “remaining yarn”. (*6)

Based on CFCL’s minimal waste policy, we have been utilizing remaining yarn, leftover from the mass production of garments, for our upcycled exclusive products since VOL.1 to VOL.3. However, with our extraordinary growth, it has become difficult to limit the use of this yarn for only seasonal projects. The total amount of recycled polyester yarn alone over the past year is approximately 116 kg, which, when converted to Pottery Dresses, is enough to produce more than 200 dresses.

CFCL will expand directly managed stores in October 2022 and March 2023 and increase opportunities to show our proposals to you, our stakeholders. We will utilize the remaining yarn in our new products and exclusive products for our stores/POP UP stores to present a wider range of projects beyond the seasons.

*6 CFCL’s phrase “remaining yarn” is used to show our policy of letting none of our unique yarn go to waste.